Report Overview

Packaging Resins Market - Highlights

Packaging Resins Market Size:

The packaging resins market is expected to grow at a 6.71% CAGR, achieving USD 321.469 billion in 2031 from USD 217.696 billion in 2025.

Packaging Resins Market Trends:

Packaging resins market is expected to grow at a steady pace during the forecast period. Packaging resins refer to a broad category of materials used in the manufacturing of various types of packaging. These resins are typically derived from petroleum or natural gas and can be in the form of plastics such as polyethylene (PE), polypropylene (PP), polyethylene terephthalate (PET), and polystyrene (PS), among others. Packaging resins possess diverse properties like flexibility, strength, clarity, and barrier properties, making them suitable for applications such as bottles, containers, films, and bags. They play a crucial role in preserving and protecting products, enhancing shelf life, facilitating transportation, and offering consumer convenience, thereby contributing to the overall efficiency and sustainability of packaging solutions.

Packaging Resins Market Trends:

The packaging resins market is all about making and selling different kinds of materials used for packaging things. These materials are usually made from oil or gas and can be in the form of plastics like polyethylene and polypropylene. The market involves companies that provide these resins to make bottles, containers, films, and bags for various products like food, medicine, and everyday items.

Factors driving the packaging resins industry include increasing demand for lightweight and sustainable packaging solutions, growing e-commerce activities, rising consumer awareness regarding environmental impact, and advancements in packaging technologies. It's a competitive market that focuses on creating better materials to meet customer demands and environmental regulations.

Packaging Resins Market Drivers:

Increasing demand for lightweight packaging:

There is a growing trend towards lightweight packaging solutions across industries. Lightweight packaging offers benefits such as reduced shipping costs, improved fuel efficiency during transportation, and lower environmental impact due to reduced material consumption.

Growing focus on sustainability:

With increasing environmental awareness, there is a strong emphasis on sustainable packaging options. Consumers and businesses are seeking packaging materials that are recyclable, biodegradable, or made from renewable resources. This driver pushes manufacturers to develop and offer eco-friendly packaging resins.

Advancements in packaging technologies:

Technological advancements have had a significant impact on the packaging resins industry. Innovations in resin manufacturing processes, such as improved polymerization techniques and the development of high-performance additives enable the production of packaging resins with enhanced properties like barrier protection, durability, and clarity.

E-commerce boom:

The rise of e-commerce has revolutionized the retail landscape and impacted packaging requirements. Online shopping necessitates packaging that can withstand the rigors of shipping, protect products from damage, and provide an engaging unboxing experience. This has led to a higher demand for packaging resins that meet these specific e-commerce needs.

Changing consumer lifestyles and preferences:

Consumer lifestyles and preferences are evolving, driving changes in packaging requirements. Factors such as convenience, portability, product visibility, and extended shelf life play a crucial role in influencing packaging choices. Packaging resins need to adapt to these changing demands to meet consumer expectations.

Stringent regulations and environmental concerns:

Governments and regulatory bodies worldwide are implementing stricter regulations to address environmental concerns related to packaging waste, recycling, and pollution. These regulations encourage the adoption of sustainable packaging practices, pushing the packaging resins market to develop eco-friendly solutions that comply with these requirements.

Global economic growth and emerging markets:

Economic growth especially in developing regions, leads to increased consumption and demand for packaged products. As emerging markets expand, the packaging resins market experiences new growth opportunities and increased demand for packaging materials.

Positive growth in the food and beverage segment:

The flexible packaging segment in the packaging resins market is experiencing positive market growth. This can be due to several factors. Firstly, flexible packaging offers numerous advantages such as lightweight, cost-effectiveness, and versatility, making it a preferred choice for various industries including food and beverage, pharmaceuticals, and personal care. Additionally, the rise of e-commerce and convenience-oriented lifestyles has led to increased demand for flexible packaging formats like pouches, sachets, and bags. Moreover, flexible packaging materials, such as polyethylene films, have seen advancements in barrier properties and sustainability, addressing concerns related to product protection and environmental impact. These factors collectively contribute to the positive market growth of the flexible packaging segment in the packaging resins industry.

Packaging Resins Market Products offered by Key Companies:

Ecovio by BASF, is a bio-based and compostable resin that is used in a variety of packaging applications, including food packaging, disposable cups, and cutlery. It is made from renewable resources, such as corn starch and sugarcane, and it is biodegradable in industrial composting facilities.

Norly GTX by SABIC, is a high-performance, high-heat-resistant resin that is used in a variety of packaging applications, including hot-fill bottles, food trays, and pharmaceutical packaging. It is known for its excellent mechanical properties, its resistance to high temperatures, and its chemical resistance.

Packaging Resins Market Geographical Outlook:

The Asia-Pacific region is anticipated to hold a significant share:

The Asia-Pacific region is expected to hold a significant share of the packaging resins market. The region has a large and rapidly growing population, driving increased consumption and demand for packaged goods across various sectors. Also, countries like China and India are witnessing significant economic growth, resulting in higher disposable incomes and changing lifestyles. Additionally, the rise of e-commerce and the increasing urbanization in the region are fueling the demand for efficient packaging solutions. Moreover, Asia-Pacific countries have a strong manufacturing base and are major exporters, further contributing to the packaging resins market growth in the region.

Packaging Resins Market Key Developments:

In May 2023, Covestro introduced Decovery CQ 6010, an innovative bio-based resin that fills the recyclability gap in food packaging. This resin replaces both PE and aluminum layers, offering moisture and oil barrier properties. Approximately 37% of the resin is derived from plant-based sources like bark, castor beans, and corn.

In Feb 2022, SCG Chemicals introduced "Circular PP," a high-quality post-consumer recycled resin (PCR) made from recycled feedstock using advanced recycling technology. This innovation is part of SCG GREEN POLYMER™, offering sustainable solutions in the form of recycled resin.

List of Top Packaging Resins Companies:

Reliance Industries Limited

Indorama Ventures Public Company Limited

DuPont

Exxon Mobil Corporation

Braskem (Odebercht)

Packaging Resins Market Scope:

| Report Metric | Details |

|---|---|

| Study Period | 2021 to 2031 |

| Historical Data | 2021 to 2024 |

| Base Year | 2025 |

| Forecast Period | 2026 – 2031 |

| Companies |

|

Report Metric | Details |

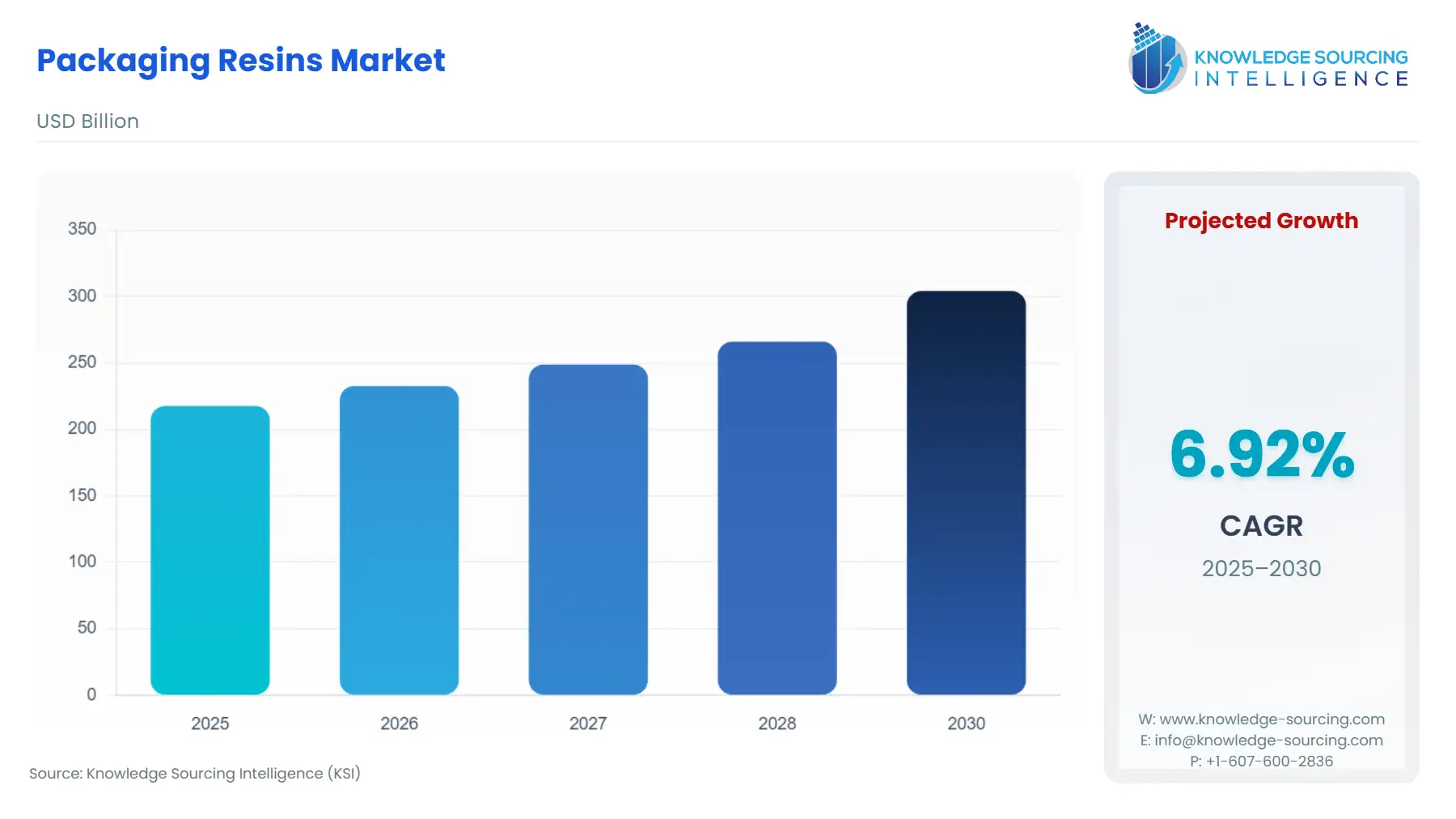

Packaging Resins Market Size in 2025 | USD 217.696 billion |

Packaging Resins Market Size in 2030 | USD 304.201 billion |

Growth Rate | CAGR of 6.92% |

Study Period | 2020 to 2030 |

Historical Data | 2020 to 2023 |

Base Year | 2024 |

Forecast Period | 2025 – 2030 |

Forecast Unit (Value) | USD Billion |

Segmentation |

|

Geographical Segmentation | North America, South America, Europe, Middle East and Africa, Asia Pacific |

List of Major Companies in Packaging Resins Market |

|

Customization Scope | Free report customization with purchase |

Packaging Resins Market Segmentation:

By Resin Type

High-density Polyethylene

Low-density Polyethylene

Polyethylene Terephthalate

Polypropylene

Others

By Application

Food &Beverage

Cosmetics &Personal Care

Healthcare

Others

By Packaging Type

Flexible Packaging

Rigid Packaging

By Geography

North America

USA

Canada

Mexico

South America

Brazil

Argentina

Others

Europe

Germany

France

United Kingdom

Spain

Others

Middle East and Africa

Saudi Arabia

UAE

Others

Asia Pacific

China

India

Japan

South Korea

Indonesia

Thailand

Others