Seeking Colors: Unveiling the Magnificence of Iron Oxide Pigments

Because of their exceptional qualities, iron oxide pigments are flexible colorants that are extensively employed in a variety of sectors. These pigments, which are made from iron oxide minerals, are good for a variety of applications due to their high tinting power, great lightfastness, and chemical stability. Iron oxide pigments are widely used in the construction sector to color bricks, asphalt, and concrete, giving structures and infrastructure strength and visual appeal. They are also utilized in the production of ceramics, paints, varnishes, and plastics, where they add vivid and durable colors. Furthermore, because iron oxide pigments are non-toxic and inert, they are used in the pharmaceutical and cosmetics sectors. Iron oxide pigments are essential in many industries due to their wide range of uses and advantageous qualities, which boost products and materials. Join us as we explore the "Iron Oxide Pigments" in this article that has evolved the industry.

Iron Oxide Pigments:

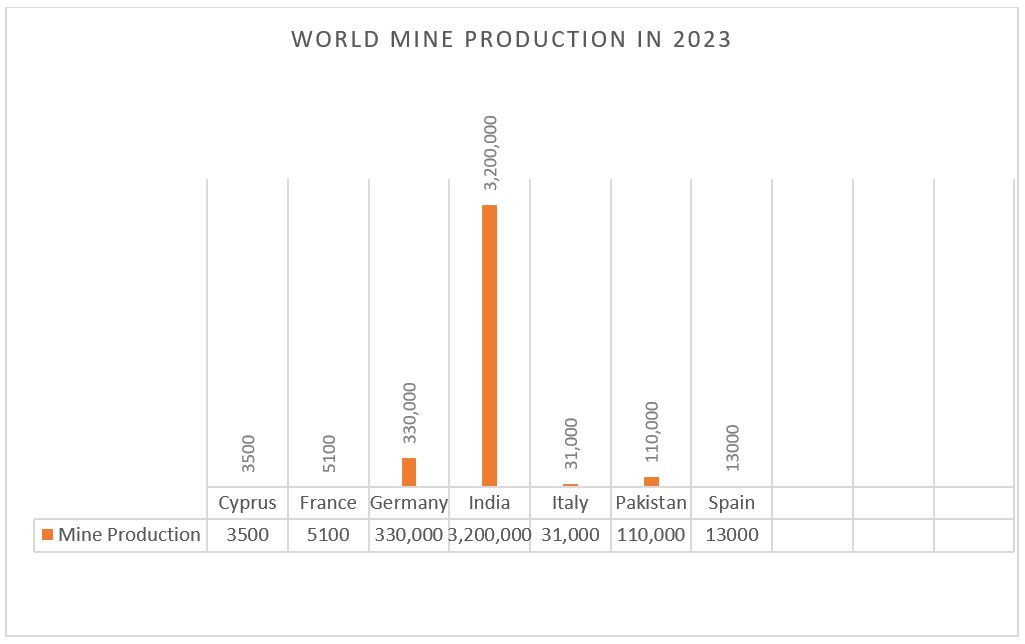

Source: USGS

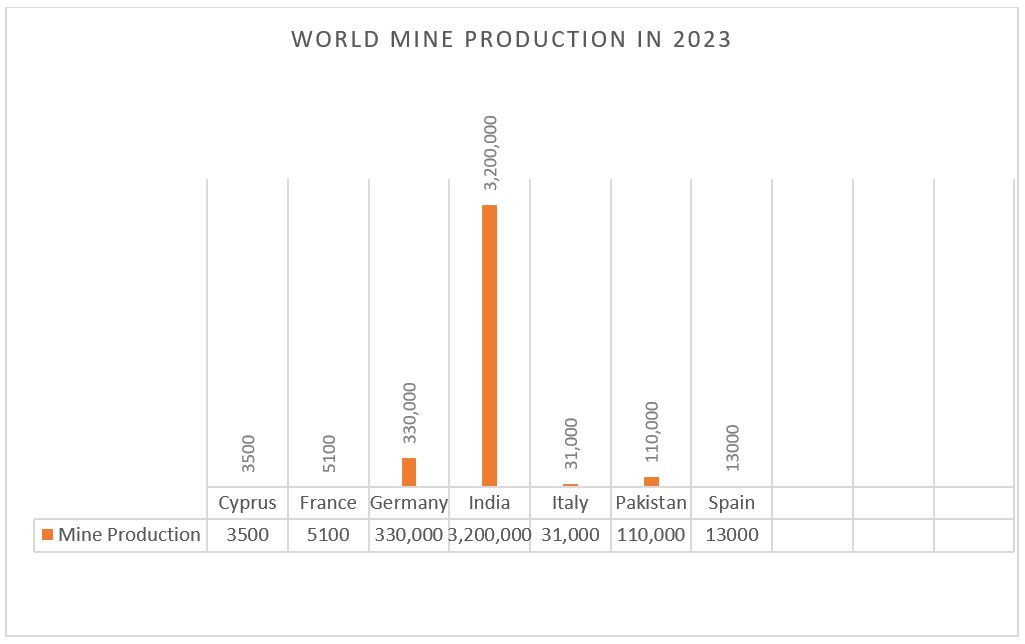

Source: USGS

- Yellow Iron oxide Pigment

- Red Iron Oxide Pigment

- Black Iron Oxide Pigment

- Orange Iron Oxide Pigments

Source: USGS

Source: USGSGet in Touch

Interested in this topic? Contact our analysts for more details.

Latest Thought Articles

Top OSAT Companies Driving Semiconductor Assembly and Test Services Worldwide

Recently

EV Charging Stations Market Outlook: Smart Charging, Fast Charging, and Regional Expansion

Recently

Future of Corporate Wellness: Global Trends and Regional Outlook

Recently

Regional Breakdown of the Mechanical Keyboard Market: Who Leads and Why?

Recently