Top 5 Innovations Transforming the Lubricants Market

Automotive Lubricants Market Insights

Lubricants are critical for providing efficient lubrication to automotive parts, reducing friction in vehicles. Beyond this primary function, automotive lubricants also clean and cool engine components, prevent rust and corrosion, and enhance overall performance. These lubricants can be solid, oil-based, plastic, or a combination, with oil and grease being the most common forms. The automotive lubricants market is driven by technological advancements that enable the development of high-performance lubricants capable of withstanding extreme temperatures and pressures. These innovations make lubricants suitable for demanding applications where conventional options fall short or require frequent replacement.Dive Deeper into the Automotive Lubricants Market

This article provides an overview. Our comprehensive market report offers detailed insights, including market size, growth forecasts, and competitive analysis to help you navigate the global automotive lubricants industry.- ? Market Size & Growth Projections

- ? Key Player Strategies & Market Share

- ? Regional Trends & Applications

1. Efficient Usage of Lubricants in the Automotive Segment

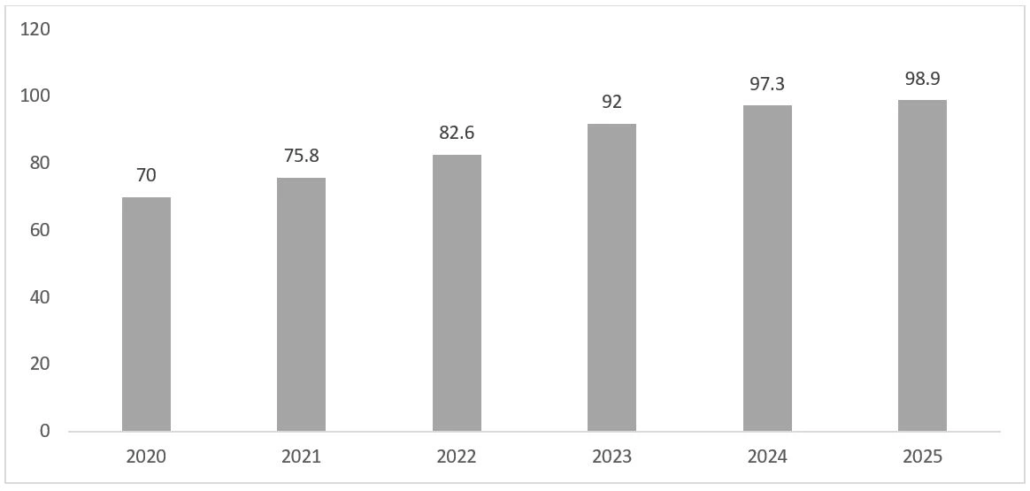

Lubricants are essential for the smooth operation of vehicles, reducing corrosion and maintaining optimal engine temperatures, which extends the lifespan of critical components. Engine oils, for instance, lubricate internal combustion engines, protect against corrosion, reduce wear, and ensure seamless engine performance. In Europe, Germany leads the automotive manufacturing industry, hosting brands like Audi, BMW, Volkswagen, Mercedes-Benz, and Porsche. According to Germany Trade and Invest (GTAI), German manufacturers produced over 15.6 million vehicles in 2021, including 3.1 million passenger cars and 351,000 commercial vehicles. The shift toward electric vehicles, supported by government initiatives targeting all-electric cars by 2024, is also driving lubricant demand. Additionally, global light vehicle production is projected to rise from 70 million units in 2020 to 98.9 million units by 2025, further fueling the lubricants market. Figure 1: Global Light Vehicle Production Trend, in Million Units, 2020 to 2025 Source: Germany Trade and Invest

In the APAC region, factors like population growth and rising vehicle production, particularly in China and India, are boosting lubricant demand. According to OICA, China produced 26,123,767 cars in 2023, including 4,037,209 commercial vehicles, while India produced 4,783,628 cars, including 1,067,878 commercial vehicles.

Source: Germany Trade and Invest

In the APAC region, factors like population growth and rising vehicle production, particularly in China and India, are boosting lubricant demand. According to OICA, China produced 26,123,767 cars in 2023, including 4,037,209 commercial vehicles, while India produced 4,783,628 cars, including 1,067,878 commercial vehicles.

Explore the Electric Vehicle Market

Lubricants are evolving to meet the needs of electric vehicles. Discover our in-depth report on the Global Electric Vehicle Market for trends, forecasts, and innovations.2. Key Developments in the Lubricant Market

Strategic innovations and partnerships are driving market growth. Notable developments include:- July 2022: Shell USA Inc. announced a merger agreement with Shell Midstream Partners L.P., acquiring common units for approximately USD 1.96 billion.

- August 2022: Valvoline agreed to sell its global products business for $2.65 billion, aiming to transform into a pure-play automotive service provider with a target of over 20% earnings per share growth.

- May 2023: ExxonMobil announced a USD 110 million investment to build a lubricant manufacturing plant in Maharashtra, India, with a capacity of 159,000 kiloliters annually, set to begin operations by late 2025.

- July 2024: TotalEnergies acquired Tecoil, a Finnish company specializing in Re-Refined Base Oils (RRBOs), enhancing production of high-performance, eco-friendly lubricants.

3. Nanotechnology as Lubricant Additives

Lubrication involves interposing solid, liquid, or gaseous substances between surfaces to minimize friction and wear. Additives in commercial lubricants enhance properties like friction reduction, corrosion resistance, and viscosity. Nanoparticles, ranging from 1 to 100 nanometers, are increasingly used as additives to improve tribological properties. Key mechanisms include:- Ball Bearing Effect: Spherical nanoparticles act as nanometric ball-bearings, reducing sliding friction by enabling a mix of sliding and rolling.

- Protective Film Formation: Nanoparticles form a thin protective film on surfaces, reducing friction and wear.

- Mending Effect: Nanoparticles deposit on surfaces, filling scars and grooves to compensate for material loss.

- Polishing Effect: Nanoparticles reduce surface roughness through abrasion, minimizing friction and wear.

4. Strategic Revolutionizing Megatrends

Lubricants are vital for industrial and automotive applications, ensuring minimal friction and efficient operation. In the automotive sector, advanced lubricants are critical for the transition to electric vehicles. The Lubrication-as-a-Service (LaaS) model is gaining traction, offering service-based solutions with continuous monitoring to optimize equipment performance and reduce downtime. Disruptive technologies include:- Lubricant-Free Polymer Bearings: Companies like igus GmbH offer self-lubricating, maintenance-free polymer bearings that operate in dry conditions, reducing costs and dirt buildup.

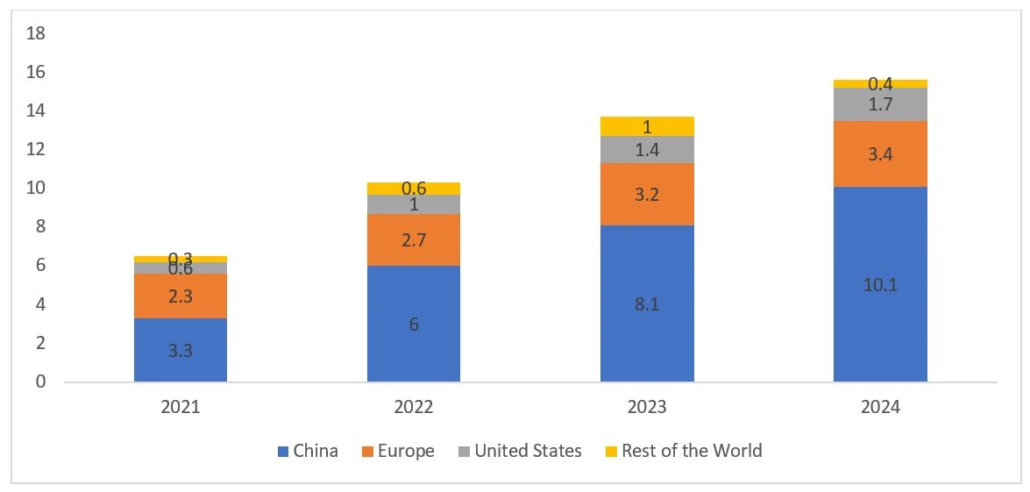

- EV-Compatible eFluids: The rise in electric vehicle sales, projected to reach 17 million by the end of 2024 (IEA), is driving demand for specialized fluids like brake fluid, transmission fluid, and greases tailored for EVs.

Source: IEA

Source: IEA

5. Automated Lubrication Systems

Automated lubrication systems are critical for components like gears, bearings, and chains, delivering precise lubrication to enhance performance and reduce maintenance costs. Benefits include:- Cost Effectiveness: These systems reduce labor costs, minimize lubricant waste, and lower energy consumption by maintaining optimal lubrication.

- Safety and Security: Automated systems eliminate the need for workers to access hazardous areas, while real-time monitoring enhances operational reliability.

Discover the Industrial Lubricants Market

Automated lubrication systems are transforming industrial applications. Get our in-depth report on the Industrial Lubricants Market for trends, forecasts, and strategic insights.Unlock Strategic Insights with Our Market Research

This overview highlights key trends. Dive into our comprehensive reports for detailed data and analysis to stay ahead in the lubricants industry. Each report provides actionable insights, forecasts, and competitive analysis to drive your business forward.Get in Touch

Interested in this topic? Contact our analysts for more details.

Latest Thought Articles

Top OSAT Companies Driving Semiconductor Assembly and Test Services Worldwide

Recently

EV Charging Stations Market Outlook: Smart Charging, Fast Charging, and Regional Expansion

Recently

Future of Corporate Wellness: Global Trends and Regional Outlook

Recently

Regional Breakdown of the Mechanical Keyboard Market: Who Leads and Why?

Recently