The Future of Insulated Shipping Boxes: Technological Developments and Market Dynamics

Insulated Shipment Packaging refers to several different packaging types – both small wraps or even big containers meant for shipping commodities. Insulated shipping boxes serve to keep products from getting damaged as a result of temperature changes during transportation because it creates insulation around the temperature-sensitive products; thereby preventing heat transfer between the packaging’s interior and exterior. Further, the demand for food and beverage products as well as personal care items has increased. These industries are expected to increase market demand as they use insulated shipping boxes as their final product.

Further, the increasing trend of organically grown produce all over the world is among the significant factors responsible for advancements in such industry. One of the reasons insulated shipping boxes are essential is because there is an increasing demand for medical drugs. In developed countries such as China and Japan where people live longer than before are suffering from various chronic illnesses, this has resulted in the growth of the international pharmacy market, with Asian states being among those showing the highest rates of expansion as compared to other parts of the globe. Some pharmaceuticals are typically shipped in insulated containers which include blood, vaccines, and medications that are sensitive to temperature.

Moreover, the adoption of environmentally friendly packaging techniques in insulated shipper space is gaining more and more attention from businesses. For instance, the product line-up of Atlas Molded Products, a division of Atlas Roofing Corporation, included DuraTherm BDT®, a biodegradable technology, in September 2023, for cold chain handling, transportation, and storage, more environmentally friendly packaging options are available with products like DuraTherm BDT.

Additionally, Hydropac launched the PharmaPac range of thermal packaging solutions in November 2023 to solve delivery problems and meet regulatory requirements for temperature-sensitive medications and vaccines. The polystyrene box, ice packs, thermal filter pack, and universal payload tray make up the PharmaPac Genesis.

Global production Trends

A key component of paper-based packaging is the idea of cellulose insulation which is increasing the market demand. The cellulose production process gives insulation materials a consistency that is comparable to conventionally used packaging materials, particularly those based on wool. Paper-based insulation materials with recycled content are being produced and consumed at an increasing rate, but due to the global wastepaper disposal issue, their adoption rate has been decreasing over time.

Further, Expanded Polypropylene (EPP) shippers are expanding due to the growing demand for effective cold supply chain solutions. The primary target audience for EPP-based boxes is food professionals and those involved in the logistics and health sectors. Eutectic plates can be added to EPP boxes to further enhance their performance.

End Use Case

The food and beverage sector has emerged as the dominant force in the insulated shipping boxes market as the food and beverage industries are using more and more insulated packaging. The growth rate is caused by variables like rising packaged food demand and rising ready-to-eat food consumption. Frozen food packs should be made in a way that helps keep them at a constant temperature during transportation as well as in storage so that they remain safe and of high quality throughout the whole distribution process. The said packs should be built in such a way that they are thermally insulated and have within them enough cooling elements for maintaining the product at a steady low temperature. Insulated shipping boxes are necessary as they restrict heat transfer from the outside environment to the interior of the package, which delays the point at which the temperature inside the package equalizes with the outside temperature. It is therefore expected that the broad application and widespread use of insulated packaging in the food and beverage industries will significantly propel the growth of the insulated packaging market in this industry throughout the forecast period.

Market Dynamics and Drivers

In the automotive and transportation sectors, high-value parts, components and surfaces are enclosed and safeguarded within the packaging during importation and exportation. Therefore, as manufacturing becomes more automated, there will be a greater need for insulated packages, which will propel the market. According to the International Trade Administration (ITA), China is the largest automobile market in the world, and the Chinese government projects that by 2025, 35 million cars will have been produced which results in the reduced costs of insulated packaging and enhancing productivity and leads to error-free supply chains.

Further, the rising global need for organic fruits and vegetables is the main force behind the sector. Different types of fruits and vegetables are grown with the help of organic farming methods across the globe. Therefore, such substances are frequently utilized as wrapping materials for fruit during transit to sustain their freshness. The surge in drug demand across the globe is one of the major forces behind insulation box use during shipping. The growth of the global medical industry has been facilitated by the rising number of individuals with enduring disorders and aged populations in countries like China and Japan. In many instances, insulated shipping boxes are frequently utilized to convey pharmaceutical materials such as blood vaccinations, and drugs that require specific temperature levels during storage or transportation, which in turn leads to high demand hence an increased size for insulation. For instance, by the end of 2023, the market had grown by 2% to £3.2 billion, nearly twice as much as it had in 2011.

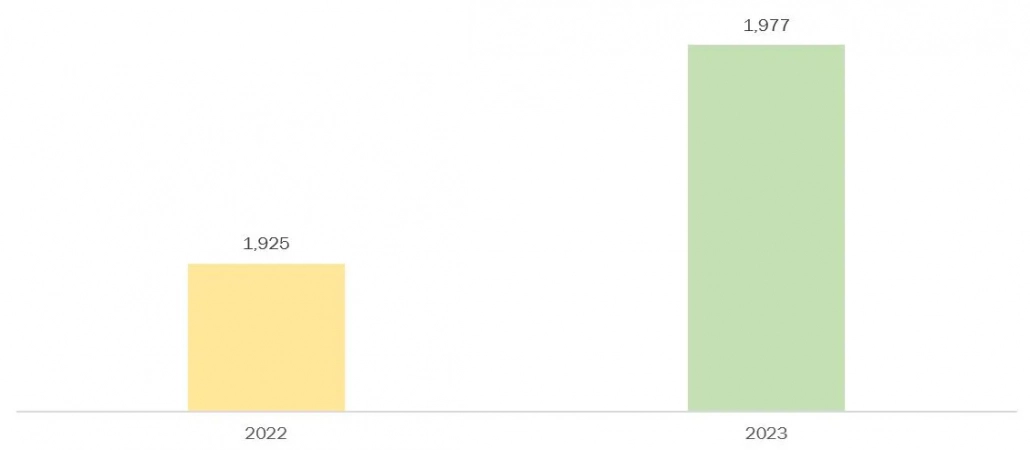

Figure 1: Sales of Organic Products in Supermarkets, in USD Millions, 2022 to 2023

Source: Organic Research Center

Key Developments

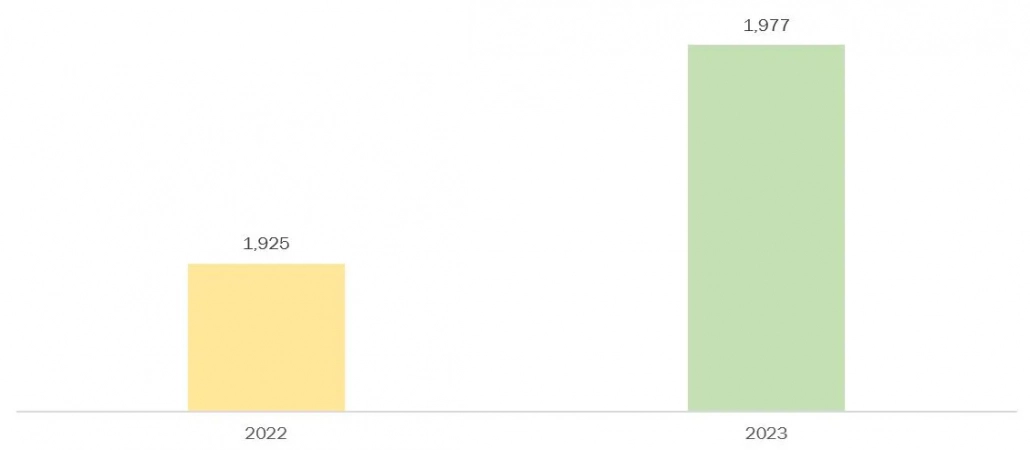

Source: Organic Research Center

Key Developments

Source: Organic Research Center

Key Developments

Source: Organic Research Center

Key Developments

- In September 2023, Phase-change Material (PCM) and Pluss Advanced Technologies (PLUSS) have partnered to introduce two novel temperature-controlled packaging options for the pharmaceutical sector, the Celsure® VIP Multi-Use Parcel Shipper series and the Celsure® XL Pallet Shipper series. These recently created goods are an excellent substitute for costly rental containers and traditional gel pack solutions.

- In March 2023, Peli BioThermal announced the expansion of its well-known range of reusable Cr?do shippers, which offer protection for deep-frozen payloads. Products will assist in addressing the increasing need to safely deliver temperature-sensitive biologics as well as time-sensitive cell and gene therapies to patients. The recently introduced Cr?do Cube Dry Ice shippers provide deep frozen payload protection for up to and frequently longer than 144 hours.

| Subscribe Us |

Get in Touch

Interested in this topic? Contact our analysts for more details.

Latest Thought Articles

Top OSAT Companies Driving Semiconductor Assembly and Test Services Worldwide

Recently

EV Charging Stations Market Outlook: Smart Charging, Fast Charging, and Regional Expansion

Recently

Future of Corporate Wellness: Global Trends and Regional Outlook

Recently

Regional Breakdown of the Mechanical Keyboard Market: Who Leads and Why?

Recently