Pine-Derived Materials Make a Way Towards Sustainable Future

Pine-derived chemicals manifest an amazing range of chemicals taken from various pine tree parts such as the bark, wood, and needles. These chemicals are extensively used by many industries in diverse ways such as the manufacture of adhesives, paints, and their coatings, fragrances, flavors, and pharmaceuticals among others. Moreover, pinewood chemicals are used in cosmetics, vitamin intermediates, pine oil disinfectants, insect repellents, aroma and perfumes, and food and beverage flavouring among others.

This pine chemical industry (PCI) is clearly first and foremost the pioneer of using biomass resources to manufacture sustainable products from a renewable source at the same time. The major raw materials, crude tall oil, and crude sulphate turpentine are always procured during the pulping of the evergreen, cone-bearing trees. Sawdust, a leftover from the processing of wood, also has applications that benefit the environment, such as filtering water for drinking and cleaning auto emissions.

Global Production Trends

Pine trees are a crucial supplier of chemicals of pine origin which are employed in a broad range of commerce. These chemicals can be extracted from oleoresin through distillation or from the carbonized wood by-products. Among the wide variety and natural ability to reproduce, pine trees are among the best sources of these bio-based alternatives to petrochemicals.

Initially, the market is boosted by the fact that consumers and industry players are seeking sustainable and bio-based options as alternatives. Pine chemicals present a sustainable latent as a replacement for petrochemicals. Environmental issues become more and more concerning issues thus, industries are looking at environmentally acceptable solutions with an increased use of bio-based chemicals.

In addition, the expansion of wood pulp and paper production is greatly linked to the pine-based chemical market. The main process by which a paper is produced, known as Kraft pulping, among many resulting components, is called tall oil which is an important material source for pine chemicals. As a result, the demand for paper products does not decrease, the production of pine-derived chemicals increases constantly.

Based on regional trends, there will be an Asia-Pacific area that will show tremendous growth. The booming manufacturing sector combined with the demand for construction projects in this region produces a great deal of consumption of pine chemicals utilized in the manufacture of adhesives, coatings, and other industrial applications. For instance, according to the State Council China published an article in May 2024, it states that the country produced 22.42 million tonnes of machine-made paper and paperboard, which was an 11.9 percent increase compared to the previous year 2022. The sales revenue of the paper industry surged by 7.5 % with the operating revenue reaching 213.55 billion yuan (about 30.05 billion US dollars) after one year. Thus, the overall sales amount to 6.42 billion yuan in the first quarter in the year 2023, which is a 336.7% increase compared to the same period last year. Overall, the global consumption of pine-based chemicals is on a growing trend. The expansion in the pulp and paper industry as well as rising demand across diverse application sectors are all the key market growth drivers to look forward to in the years ahead.

Pine-Derived Chemical Use Cases

The chemicals derived from pine are famous for their environmentally safe character and versatile functions and are widely used in different industries.

The pine chemicals are a fundamental component in the construction industry. Resin from gum acts as the tackifier in the adhesives which are used in lumber bonding, plywood manufacturing, and furniture assembly. In addition, the chemicals from pine help to boost durability and adhesion in paints, varnishes, and coatings.

Paper and Packaging Pine chemicals are an integral part of the pulp and paper industries. Paper pulping process, which is called Kraft, produces tall oil with it serving as a basic raw material for pine chemicals. Beyond these indirect roles, the chemicals obtained from pine trees can be directly used as sizing agents, strengthening additives, and wet-end additives during papermaking. It increases water resistance, strength, and general paper quality.

Adding skincare and beauty products is the surprising purpose of the pine tree extracts. Fats and oils as well as sterols are used as basic building blocks that are responsible for providing a moisturizing and soothing effect. Furthermore, the pine plant sources evergreen essential oils to support fragrances and contribute a natural scent to numerous cosmetics.

Food and Beverage Sector Pine chemical applications have gained widespread utilization in the food and beverage industries. Specific pinewood by-products such as herbal flavors are allowed to be used as flavoring agents with citrusy or piney nuances which you can find in candies, sodas, and cakes.

Market Dynamics and Drivers

The demand for pine-derived chemicals is witnessing continuous growth, as the presence of factors like their wide range of functions along with renewability, are giving them unique application advantages.

The main reason for this growth is the huge trend that is happening in present days where consumers are looking more and more for ecological options. Innovations and discoveries in renewable and bio-based resources are an integral part of an ever-increasing consumers’ awareness of the environment and thus many industries search for these alternatives to the traditional petrochemical materials. Pine chemicals, native to a local source which is owned abundantly and replenished naturally, provide one possible answer to this change. The answer highlights sustainable and environmentally friendly solutions.

For instance, according to Blue Yonder the supply chain company published article on a consumer survey regarding sustainability in 2024 it states that wide number of consumers accept the benefits of sustainability, and they are ready to pay more for sustainable products. A recent study implies that 65% of customers are ready to pay more money on goods that are green-friendly. Furthermore, customers anticipate that retailers and brands embrace diverse environmental practices. According to the study, 61% of people would give preference to products utilizing recycled content or choosing packaging with less food or inventory waste. Furthermore, as many as 39% of consumers expect retailers to decrease the carbon footprint of physical stores or operations, and 34% want a decrease in transportation carbon footprint as well. This evidence shows the increasing role of sustainability in consumer choice and the necessity for companies to meet consumers' expectations in this regard.

Moreover, the pulp and paper industry is an important contributor to the market growth. The key Kraft pulping process generates tall oil, the pine chemicals starting material. The continuous demand for paper products guarantees an uninterrupted supply of tall oil, which is further processed to produce pine-based chemicals.

Moreover, scientific growth and technological development are also key drivers behind the market expansion. Advanced extraction and processing technologies are, in turn, bringing higher yields and more economical production of pine extracts. Apart from that, continuous studies on the new applications and performances of these chemicals extend the boundaries of their usage.

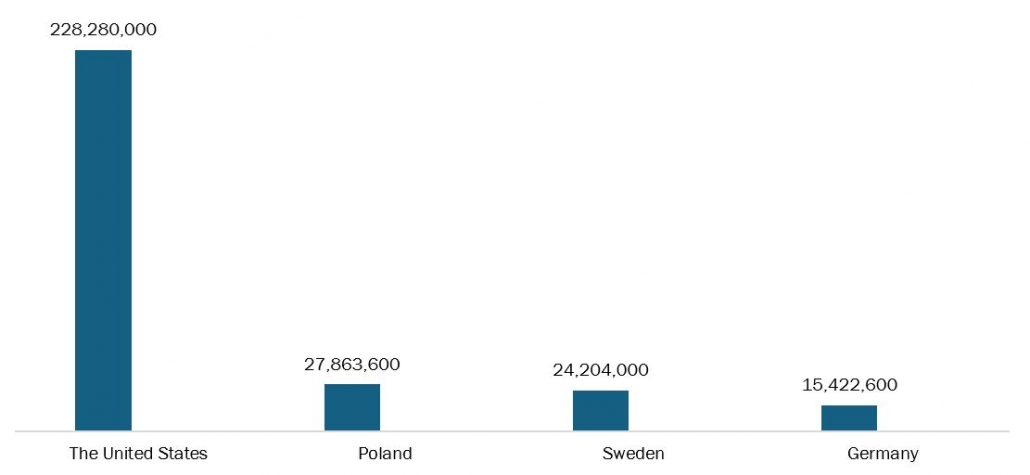

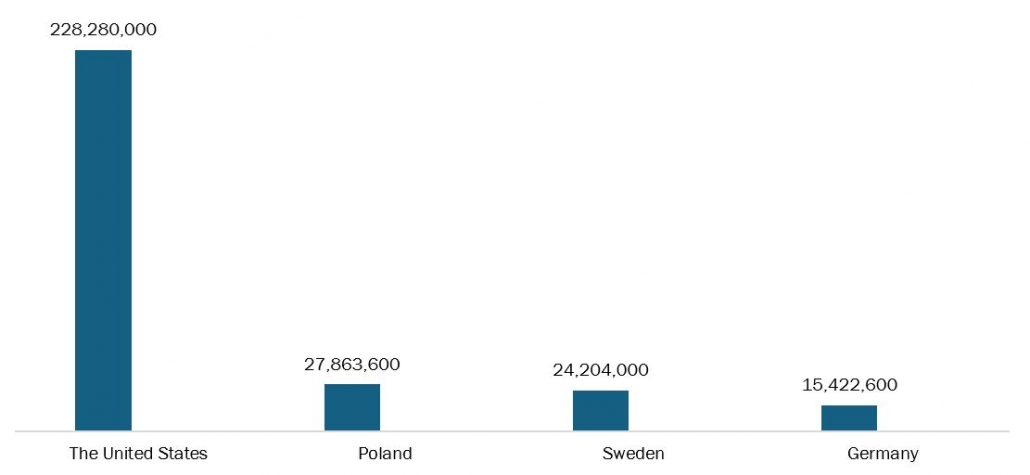

In 2023, the topmost tall oil exporters were the United States with 22.84 million kg, Poland with 2.73 million kg, Sweden with 2.36 million kg, and Germany with 1.46 million kg.

Figure 1: The Tall Oil Exporter Countries (2023 Qty Unitkg)

Source: World Integrated Trade Solution

Market Challenges

Nevertheless, the market for pine-derived chemicals has yet to meet high expectations, despite its promising potential. Instability in crude oil prices that are in some cases used as substitutes for certain applications is a danger to the competitiveness of pine chemicals. Additionally, the harmful emissions resulting from the highly energy-consuming extraction process demand a constant development of more environmentally friendly methods. Also, tough environmental regulations might lead to an increase in production costs or access to the available resources. To ensure the future prosperity of the market, it will be necessary to address these challenges through the implementation of technological advancements and environmentally friendly extraction strategies.

Emerging Opportunities and Innovations

Innovation in the production of chemicals from pine is the main driver of the demand curve of the market. Supercritical fluid extraction technology and microwave-assisted extraction methods are becoming increasingly popular with regard to green chemistry and delivering ecologically sustainable ways to extract valuable substances. This extends the range of products that could be produced from pine biomass. A research also reveals that byproducts that are bio-based fuels and green solvents can be used in the energy and chemical industries for sustainable alternatives.

Key Developments

Source: World Integrated Trade Solution

Market Challenges

Nevertheless, the market for pine-derived chemicals has yet to meet high expectations, despite its promising potential. Instability in crude oil prices that are in some cases used as substitutes for certain applications is a danger to the competitiveness of pine chemicals. Additionally, the harmful emissions resulting from the highly energy-consuming extraction process demand a constant development of more environmentally friendly methods. Also, tough environmental regulations might lead to an increase in production costs or access to the available resources. To ensure the future prosperity of the market, it will be necessary to address these challenges through the implementation of technological advancements and environmentally friendly extraction strategies.

Emerging Opportunities and Innovations

Innovation in the production of chemicals from pine is the main driver of the demand curve of the market. Supercritical fluid extraction technology and microwave-assisted extraction methods are becoming increasingly popular with regard to green chemistry and delivering ecologically sustainable ways to extract valuable substances. This extends the range of products that could be produced from pine biomass. A research also reveals that byproducts that are bio-based fuels and green solvents can be used in the energy and chemical industries for sustainable alternatives.

Key Developments

Explore the Pine-Derived Chemicals Market

Discover the full potential of pine-derived chemicals with our comprehensive market report, offering detailed insights into growth trends, applications, and competitive landscapes.- ? Market Size & Growth Projections

- ? Key Industry Applications

- ? Regional Market Analysis

Dive into the Adhesives Market

Pine-derived chemicals are critical in adhesive production. Explore our in-depth report on the global adhesives market for trends, forecasts, and key player insights. Source: World Integrated Trade Solution

Market Challenges

Nevertheless, the market for pine-derived chemicals has yet to meet high expectations, despite its promising potential. Instability in crude oil prices that are in some cases used as substitutes for certain applications is a danger to the competitiveness of pine chemicals. Additionally, the harmful emissions resulting from the highly energy-consuming extraction process demand a constant development of more environmentally friendly methods. Also, tough environmental regulations might lead to an increase in production costs or access to the available resources. To ensure the future prosperity of the market, it will be necessary to address these challenges through the implementation of technological advancements and environmentally friendly extraction strategies.

Emerging Opportunities and Innovations

Innovation in the production of chemicals from pine is the main driver of the demand curve of the market. Supercritical fluid extraction technology and microwave-assisted extraction methods are becoming increasingly popular with regard to green chemistry and delivering ecologically sustainable ways to extract valuable substances. This extends the range of products that could be produced from pine biomass. A research also reveals that byproducts that are bio-based fuels and green solvents can be used in the energy and chemical industries for sustainable alternatives.

Source: World Integrated Trade Solution

Market Challenges

Nevertheless, the market for pine-derived chemicals has yet to meet high expectations, despite its promising potential. Instability in crude oil prices that are in some cases used as substitutes for certain applications is a danger to the competitiveness of pine chemicals. Additionally, the harmful emissions resulting from the highly energy-consuming extraction process demand a constant development of more environmentally friendly methods. Also, tough environmental regulations might lead to an increase in production costs or access to the available resources. To ensure the future prosperity of the market, it will be necessary to address these challenges through the implementation of technological advancements and environmentally friendly extraction strategies.

Emerging Opportunities and Innovations

Innovation in the production of chemicals from pine is the main driver of the demand curve of the market. Supercritical fluid extraction technology and microwave-assisted extraction methods are becoming increasingly popular with regard to green chemistry and delivering ecologically sustainable ways to extract valuable substances. This extends the range of products that could be produced from pine biomass. A research also reveals that byproducts that are bio-based fuels and green solvents can be used in the energy and chemical industries for sustainable alternatives.

Discover the Lubricant Additives Market

Pine-derived chemicals are innovating the lubricant industry. Access our detailed report on the lubricant additives market to uncover growth drivers and emerging trends.- In February 2024: The Kraton a company renowned for its manufacturing and sales of polymers and biochemicals in the market launched a brand-new line of bio-oils called SYLVASOLV which utilizes pine wood industrial waste as its feedstock. These high-grade oils not only offer eco-solutions for agriculture, adhesives, and lubricants but also supply ecologically acceptable alternatives for diverse industry uses.

Go from Insight to Action with Our Market Research

You've seen the overview. Now, get the detailed data and strategic analysis you need to stay ahead in the bio-based chemicals market. Explore our related, in-depth reports. Each report includes comprehensive data, forecasts, and competitive analysis to empower your business decisions.| Subscribe Us |

Get in Touch

Interested in this topic? Contact our analysts for more details.

Latest Thought Articles

Top OSAT Companies Driving Semiconductor Assembly and Test Services Worldwide

Recently

EV Charging Stations Market Outlook: Smart Charging, Fast Charging, and Regional Expansion

Recently

Future of Corporate Wellness: Global Trends and Regional Outlook

Recently

Regional Breakdown of the Mechanical Keyboard Market: Who Leads and Why?

Recently