Innovations Flash New Opportunities in the Field of Elastomeric Foam

Elastomeric, also called rubber insulation, is a synthetic material that possesses the ability to achieve insulation qualities. The rubber material is a type of closed-cell structure that consists of synthetic rubber, PVC, and the same chemical foaming agent. The components are mashed together and then given a variety of shapes, like sheets or tubes, and then the entire composition is placed into an oven to be heated up.

Elastomeric foam insulations are particularly useful in cold systems because they completely let go of condensation. The closed cell structure plus the low permeability to water vapor are the great features that offer excellent protection against moisture. On top of that, it includes the vapor barrier built right inside where the pipes and equipment are protected from corrosion under insulation (CUI). Another plus point of this insulation material is its longevity, waterproofing properties, and convenience in the installation, which confers its user-friendliness.

The field of elastomeric foam insulation is versatile and widely applied. It also finds its application in refrigeration and chilled water piping, HVAC components, interior and exterior duct systems, chillers, mechanical systems, and solar installations.

Global Production Trend

The demand is getting higher for energy-efficient elastomeric foam in several sectors than ever before because of its famous thermal and acoustic insulation features. While construction, heating & plumbing, and the HVAC industries continue applying foam for insulation purposes, efficiency in energy is however also enhanced, reducing heating and cooling costs.

Governments globally have implemented stronger laws that require buildings to have improved energy efficiency. This is what leads to the use of energy-saving materials like elastomeric foam in construction projects. For instance, in December 2023 the U.S. Department of Energy (DOE), in particular, approved stricter energy performance ratings for refrigerators and freezers of the latest models. Thus, the DOE appliance and equipment standards program has proudly served a prosperous year of standard implementation. Additionally, it is predicted that these new standards for fridges and freezers will save American families with an annual consumption of more than $36 billion in energy costs within the next 30 years. The overall improvements in energy efficiency adopted in cooking appliances and other appliances alike will translate to a bigger $1 trillion savings by 2050. Also, the more stringent rules can constitute a part of the solution by reducing harmful greenhouse gases as well. This accomplishment points to the fact that we are getting a vision of the future where our homes become more energy-efficient nationwide.

As the issue of sustainability and environmental phenomena is getting more and more attention, the construction being done in this manner has turned to sustainable building practices. Eco-compatible elastomeric foam, commonly made of recycled materials, is as good an offer as traditional insulation materials according to the green trend.

Elastomeric foam is versatile and has different forms like sheet, tube, and pipe to serve numerous application's needs. Manufacturers are working on product enhancements such as fire resistance, UV resistance, and improved chemical compatibility. It widens the elastomeric foam application sphere which is enough for multi-purpose use.

On the other hand, the elastomeric foam demand has increased significantly as a result of the fast-growing industrialization and urbanization in countries like China and India. These countries are targeting infrastructure development and that is triggering the rising demand for elastomeric foam in insulation applications.

Elastomeric Foam Use Cases

Elastomeric foams have become very popular in different industries due to their special properties- thermo-acoustic insulation. In the construction industry, it serves as a key factor leading to more efficient energy usage by cutting down on heat loss through roofing, walling, or foundations. Furthermore, the use of elastic tubes and pipes in the HVAC system greatly helps to avoid heat losses, therefore, ensuring the optimum system’s performance.

The insulating property of elastomeric foam can also be seen in electric home appliances. High-efficiency thermal insulation properties help refrigerators, freezers, and water heaters maintain constant internal temperatures which are energy-efficient and cut utility bills in half. The other application of this material to gaskets and seals is that they also prevent air leaks for a variety of appliances and electronics thus keeping their efficiency in check.

Elastomeric foam is used in the automobile industry for the purpose of noise as well as vibration absorption. Engine rooms, dashboards, and door panels lined with such foam are the main factors that cause driving inside, to be quieter and more comfortable. Furthermore, the elastomeric foam gaskets and seals are the key elements that prevent leaks and guarantee the smooth operation of other automotive parts.

In the context of packaging and cold chain management, elastomeric foam sheets and liners have a perfect role in preserving the structure of temperature-sensitive goods. The insulating effect of these packaging materials helps maintain a constant temperature during transportation and storage, providing a perfect environment for perishable goods like food and medical drugs.

Market Dynamics and Drivers

Despite showing a stable growth trend now, the elastomeric foam market has many factors working in its favor that emphasize its performance, a wide range of applications, and a favorable environmental impact.

One of the major reasons of this development is the rising need for energy efficiency in buildings. The rigorous laws and emphasis on sustainability have required the introduction of elastomeric foam for insulation in the roofs, walls, and foundations. The heat transfer is limited due to this, resulting in better performance of the building envelope and less energy consumption for heating and cooling. Furthermore, in HVAC systems, the utilization of elastomeric foam tubes and pipes enhances effectiveness by preventing heat losses, which in turn leads to energy saving.

Technological progress also makes a major contribution to the development of the market. Manufacturers are consistently endeavoring to innovate and produce elastomeric foam products with advanced characteristics. The innovations in fire resistance, UV resistance, and better chemical compatibility ensure that this material can be used across a wider range of applications in domains that have defined requirements. Take as an illustration, that fire-resistant elastomeric foam is becoming increasingly popular in construction projects because of more stringent fire safety regulations. For instance, according National Library of Medicine published article in March 2023 it states that, nanotechnology promises amazing opportunities for biomedicine with aerogel-based materials used as a flagship. These structures that are lightweight and porous present vast surface area and tunable properties. Consequently, they are broadly useful materials. Whether it is through drug delivery, tissue engineering scaffolding, wound dressing or biosensor senses, aerogels are revolutionizing the industry. The ongoing research on the biocompatible and target specific functionalities is finally paving way for the new age of health care which is completely based on nanotechnology.

Another primary factor in the growth of elastomeric foam is its versatility throughout industries. Besides construction and HVAC, it is used in the insulation of appliances, auto noise reduction and vibration damping, packaging for temperature-sensitive items, and even sporting goods for padding and support. These many applications expand the market range and opportunity for elastomeric foam.

Increased prosperity in developing economies is another factor which drives the elastomeric foam market. These territories are experiencing higher rates of urbanization and construction development, creating a surge demand for elastomeric foams in building construction, HVAC and other sectors. Government policy makers who are inclined on energy efficiency will contribute more to market growth seen within these economies.

In conclusion, therefore, the driving factors of the elastomeric foam market are diverse and diverse in nature. Since energy efficiency, technological developments, product variability, and environmental aspects are all the factors behind market growth in this area.

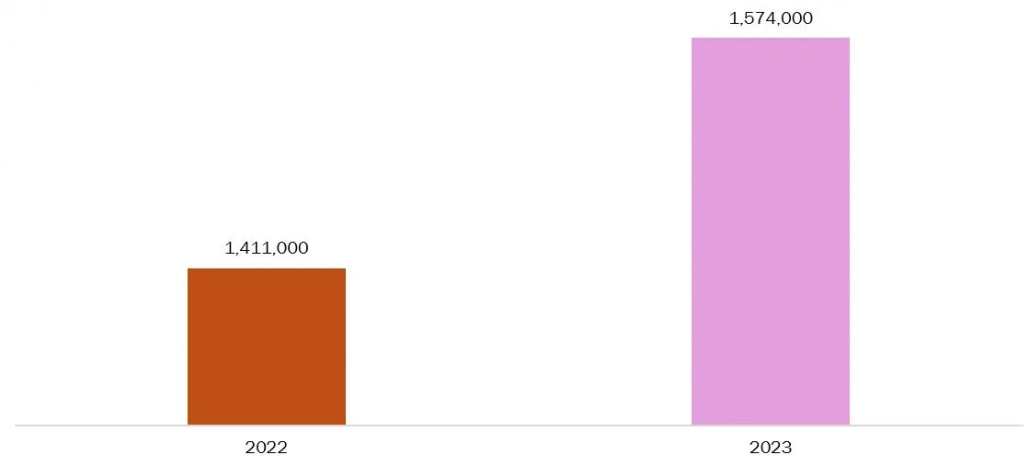

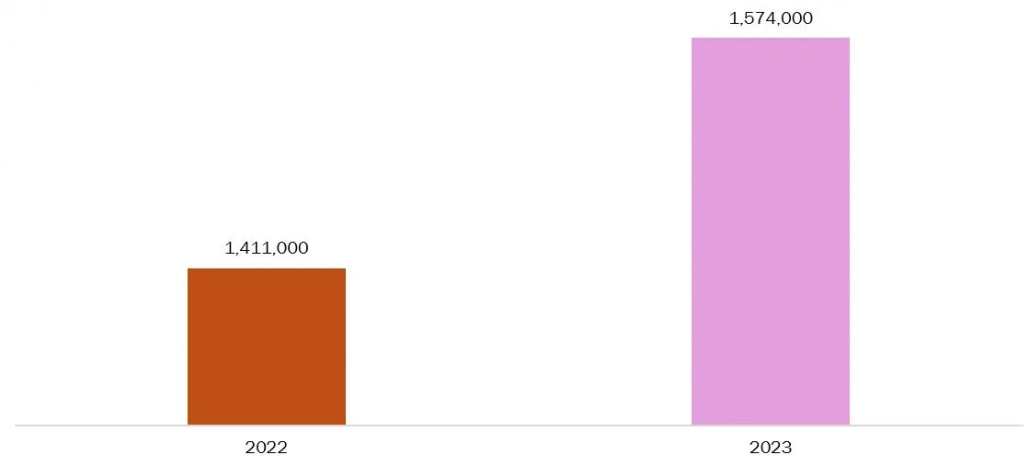

For instance, in April 2024 the United States Census Bureau and the US Department of Housing and Urban Development released recent data on quoting home construction. The data underlines that the amount of new housing delivered amounted to 1,574,000 Units in 2023. In 2022, there were 1,411,000 Units. These numbers suggest that the plan has been a success in its second, or even third year.

Figure 1: New Residential Construction in USA (2022-2024)

Source: Census.gov

Market Challenges

Although the foam elastomeric market continues to expand, it still faces a number of challenges. The fluctuation of cruder prices can influence on production cost, and market stability as well, especially for petroleum-based products. Not only in the production stages but also in the disposal and use of raw materials, strict environmental controls may cause higher costs or limit access to raw materials. Moreover, the competition for insulation materials such as mineral wool and cellulose fiber necessitates innovation constantly to keep ahead of the competition. For the market to continue to operate successfully we need to be able to take on these challenges through cost reduction, investigation for sustainable production, and by offering products with distinctive features.

Emerging Opportunities and Innovations

The elastomeric foam industry is raising the bar for innovation these days. The use of foams with aerogels is the main breakthrough in making thermal insulation and now flame-retardant options meet safety requisites in the building industry. The focus on sustainability can be observed in the way that biobased materials and the use of high recycled content are gaining increasing popularity. Such gradual shifts along with the emergence of energy efficiency and adaptability requirements across different sectors are provoking diverse applications in construction, transport, and many other sectors.

Key Developments

Source: Census.gov

Market Challenges

Although the foam elastomeric market continues to expand, it still faces a number of challenges. The fluctuation of cruder prices can influence on production cost, and market stability as well, especially for petroleum-based products. Not only in the production stages but also in the disposal and use of raw materials, strict environmental controls may cause higher costs or limit access to raw materials. Moreover, the competition for insulation materials such as mineral wool and cellulose fiber necessitates innovation constantly to keep ahead of the competition. For the market to continue to operate successfully we need to be able to take on these challenges through cost reduction, investigation for sustainable production, and by offering products with distinctive features.

Emerging Opportunities and Innovations

The elastomeric foam industry is raising the bar for innovation these days. The use of foams with aerogels is the main breakthrough in making thermal insulation and now flame-retardant options meet safety requisites in the building industry. The focus on sustainability can be observed in the way that biobased materials and the use of high recycled content are gaining increasing popularity. Such gradual shifts along with the emergence of energy efficiency and adaptability requirements across different sectors are provoking diverse applications in construction, transport, and many other sectors.

Key Developments

Source: Census.gov

Market Challenges

Although the foam elastomeric market continues to expand, it still faces a number of challenges. The fluctuation of cruder prices can influence on production cost, and market stability as well, especially for petroleum-based products. Not only in the production stages but also in the disposal and use of raw materials, strict environmental controls may cause higher costs or limit access to raw materials. Moreover, the competition for insulation materials such as mineral wool and cellulose fiber necessitates innovation constantly to keep ahead of the competition. For the market to continue to operate successfully we need to be able to take on these challenges through cost reduction, investigation for sustainable production, and by offering products with distinctive features.

Emerging Opportunities and Innovations

The elastomeric foam industry is raising the bar for innovation these days. The use of foams with aerogels is the main breakthrough in making thermal insulation and now flame-retardant options meet safety requisites in the building industry. The focus on sustainability can be observed in the way that biobased materials and the use of high recycled content are gaining increasing popularity. Such gradual shifts along with the emergence of energy efficiency and adaptability requirements across different sectors are provoking diverse applications in construction, transport, and many other sectors.

Key Developments

Source: Census.gov

Market Challenges

Although the foam elastomeric market continues to expand, it still faces a number of challenges. The fluctuation of cruder prices can influence on production cost, and market stability as well, especially for petroleum-based products. Not only in the production stages but also in the disposal and use of raw materials, strict environmental controls may cause higher costs or limit access to raw materials. Moreover, the competition for insulation materials such as mineral wool and cellulose fiber necessitates innovation constantly to keep ahead of the competition. For the market to continue to operate successfully we need to be able to take on these challenges through cost reduction, investigation for sustainable production, and by offering products with distinctive features.

Emerging Opportunities and Innovations

The elastomeric foam industry is raising the bar for innovation these days. The use of foams with aerogels is the main breakthrough in making thermal insulation and now flame-retardant options meet safety requisites in the building industry. The focus on sustainability can be observed in the way that biobased materials and the use of high recycled content are gaining increasing popularity. Such gradual shifts along with the emergence of energy efficiency and adaptability requirements across different sectors are provoking diverse applications in construction, transport, and many other sectors.

Key Developments

- In May 2023: The Huntsman renowned for chemical manufacturing for industries has been working on introducing new materials such as polyurethane, carbon nanotube, and epoxy that technology employs to elevate the combination and functionality of batteries in electric vehicles. These fast-curing materials, keeping in mind the individual specifications, can for sure increase the safety of batteries, reduce their weight, and quicken the manufacture of the underneath and up-cover parts by local and foreign firms.

| Subscribe Us |

Get in Touch

Interested in this topic? Contact our analysts for more details.

Latest Thought Articles

Top OSAT Companies Driving Semiconductor Assembly and Test Services Worldwide

Recently

EV Charging Stations Market Outlook: Smart Charging, Fast Charging, and Regional Expansion

Recently

Future of Corporate Wellness: Global Trends and Regional Outlook

Recently

Regional Breakdown of the Mechanical Keyboard Market: Who Leads and Why?

Recently