Ensuring Safety and Quality: Exploring Food Contact Paper for Packaging Solutions

Packaging materials intended for direct contact with food products are called "food contact paper" to maintain hygienic standards, safety, and legal compliance. Food-grade materials that are non-toxic, odorless, and devoid of dangerous compounds or impurities that could contaminate food are used in the production of these papers. They are frequently used to preserve freshness, stop contamination, and lengthen the shelf life of perishable foods, baked goods, sandwiches, and other food products. Food contact paper is an essential part of the food packaging business that helps to guarantee the safety and quality of food products for consumers since it is subject to strict regulations from food safety authorities.

The food industry's growing need for safe and environmentally friendly packaging options is fuelling the market for food contact paper, which is expanding steadily. Growing consumer awareness of food safety, consumers’ desire for environmentally friendly packaging materials, and developments in paper technology are important factors driving market expansion. Furthermore, food manufacturers and retailers across the globe are adopting food contact papers due to their ease, affordability, and recyclability, which is influencing the market's growth trajectory.

Fast food demand is one of the main factors driving the food contact paper market. Fast food and quick-service restaurants are becoming more and more popular among consumers due to their hectic lifestyles and on-the-go dining habits. The necessity for packaging materials, such as food contact paper, that can efficiently retain and preserve fast food items, guaranteeing freshness and safety during storage and transit, has expanded due to this development. Furthermore, the growth of food delivery services increases the need for dependable and long-lasting packaging, which is why food contact paper is essential to satisfying the packaging requirements of the fast-food sector.

Another major factor driving the market for food contact paper is the rising need for environmentally friendly packaging. Packaging materials that are recyclable, biodegradable, and have little environmental impact are preferred by customers who are becoming more and more environmentally concerned. Food contact paper satisfies these requirements and is in line with the worldwide emphasis on sustainability because it is eco-friendly and renewable. The use of environment-friendly packaging materials is also encouraged by regulatory organizations, which promote the use of food contact paper in the food and beverage sector. The market is expanding as a result of the growing demand for eco-friendly food contact paper brought on by consumers' and businesses' increased emphasis on environmental responsibility.

The market for food contact paper is mostly driven by technological improvements. Novelties in the production of paper have resulted in food contact materials possessing improved moisture resistance, barrier qualities, and durability. High-quality branding and images on food packaging are made possible by advanced printing techniques, which draw consumers' attention. The development of antimicrobial coatings for food contact sheets, which extend their shelf life and guarantee food safety, is another way that nanotechnology has helped. Additionally, traceability and transparency are provided throughout the supply chain via smart packaging solutions, such as RFID tags and QR codes on food contact paper, which also meet regulatory standards and increase consumer trust.

The market for food contact paper is expanding significantly in the kraft paper category. Due to its eco-friendly qualities, kraft paper—which is renowned for its strength, durability, and natural appearance—is becoming more and more popular in food packaging. Being biodegradable, recyclable, and composed of renewable materials, it satisfies the rising need for environment-friendly packaging options. Because it can be used for so many different food applications, including wrapping, pouches, bags, and containers, the kraft paper market benefits from its adaptability.

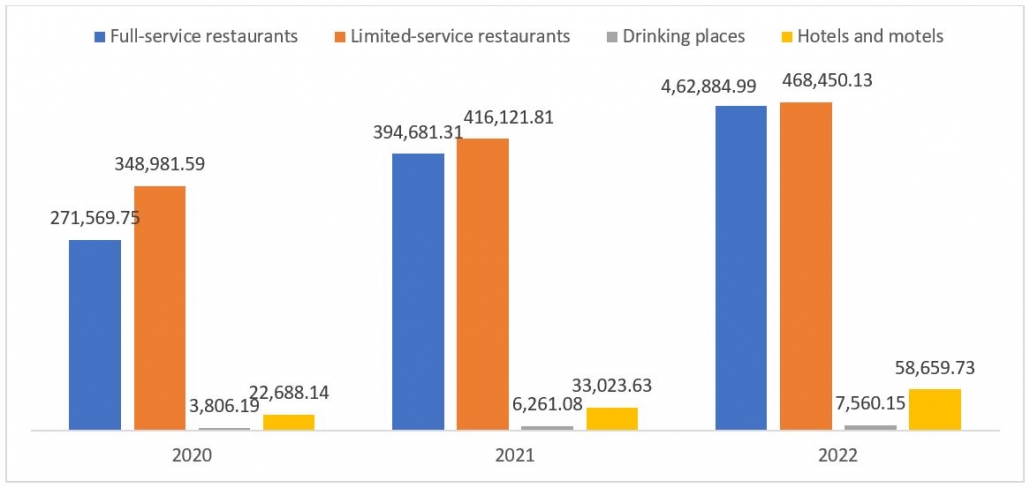

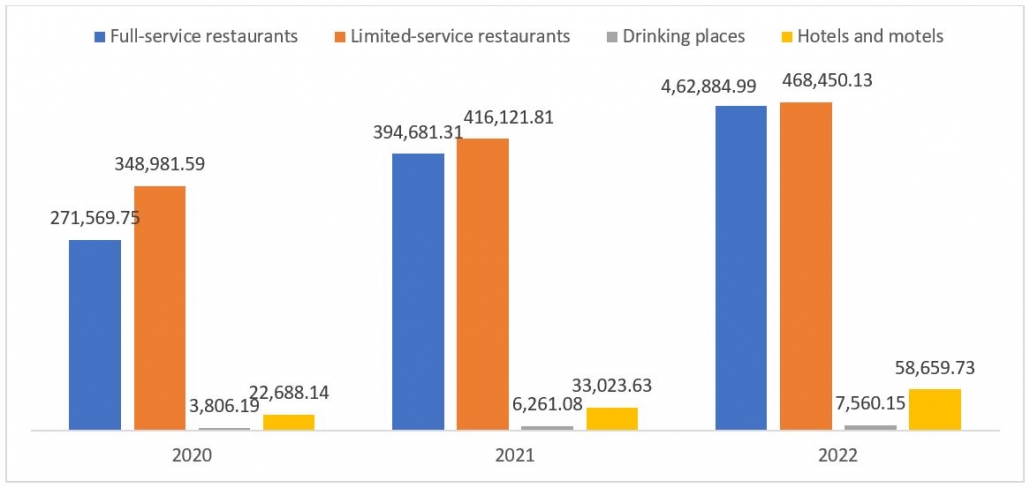

Furthermore, improvements in barrier coatings and other aspects of the kraft paper manufacturing process make it more suitable for applications involving food, which promotes market expansion and adoption. Additionally, food expenditure is increasing every year. According to the USDA, food and alcohol expenditure in full-service restaurants increased from US $2,71,569.75 in 2020 to $ 4,62,884.99 in 2022. $3,48,981.59 in 2020 to $4,68,450.13 in 2022 in Limited-service restaurants.

Figure 1: Nominal Food and Alcohol Expenditure, With Taxes and Tips for All Purchasers in the US (US$ Million), 2020-2022

Source: USDA

The food contact paper market in North America is expanding significantly due to several important factors. Safe and sustainable packaging materials are in high demand due to strict laws and growing consumer awareness of food safety. The transition to recyclable and environmentally friendly packaging options has sped up market expansion even more. Additionally, new food contact papers with improved barrier qualities and durability have been developed as a result of technological developments in paper manufacturing methods. Food contact paper is a thriving market segment in North America due in part to consumers' growing desire for convenience foods and online meal delivery services.

In conclusion, growing awareness of food safety, sustainability issues, and regulatory compliance are driving the market for food contact paper. In response to consumer expectations for packaging that is ecologically friendly, manufacturers are concentrating on creating novel solutions, such as food contact sheets that are recyclable and bio-based. Convenience foods, the growing use of online meal delivery services, and the expansion of the food packaging sector as a whole all contribute to the market's growth. The food contact paper market has a bright and sustainable future because of ongoing developments in materials and technologies and strict laws governing products that come into contact with food.

Key Developments:

Source: USDA

The food contact paper market in North America is expanding significantly due to several important factors. Safe and sustainable packaging materials are in high demand due to strict laws and growing consumer awareness of food safety. The transition to recyclable and environmentally friendly packaging options has sped up market expansion even more. Additionally, new food contact papers with improved barrier qualities and durability have been developed as a result of technological developments in paper manufacturing methods. Food contact paper is a thriving market segment in North America due in part to consumers' growing desire for convenience foods and online meal delivery services.

In conclusion, growing awareness of food safety, sustainability issues, and regulatory compliance are driving the market for food contact paper. In response to consumer expectations for packaging that is ecologically friendly, manufacturers are concentrating on creating novel solutions, such as food contact sheets that are recyclable and bio-based. Convenience foods, the growing use of online meal delivery services, and the expansion of the food packaging sector as a whole all contribute to the market's growth. The food contact paper market has a bright and sustainable future because of ongoing developments in materials and technologies and strict laws governing products that come into contact with food.

Key Developments:

Source: USDA

The food contact paper market in North America is expanding significantly due to several important factors. Safe and sustainable packaging materials are in high demand due to strict laws and growing consumer awareness of food safety. The transition to recyclable and environmentally friendly packaging options has sped up market expansion even more. Additionally, new food contact papers with improved barrier qualities and durability have been developed as a result of technological developments in paper manufacturing methods. Food contact paper is a thriving market segment in North America due in part to consumers' growing desire for convenience foods and online meal delivery services.

In conclusion, growing awareness of food safety, sustainability issues, and regulatory compliance are driving the market for food contact paper. In response to consumer expectations for packaging that is ecologically friendly, manufacturers are concentrating on creating novel solutions, such as food contact sheets that are recyclable and bio-based. Convenience foods, the growing use of online meal delivery services, and the expansion of the food packaging sector as a whole all contribute to the market's growth. The food contact paper market has a bright and sustainable future because of ongoing developments in materials and technologies and strict laws governing products that come into contact with food.

Key Developments:

Source: USDA

The food contact paper market in North America is expanding significantly due to several important factors. Safe and sustainable packaging materials are in high demand due to strict laws and growing consumer awareness of food safety. The transition to recyclable and environmentally friendly packaging options has sped up market expansion even more. Additionally, new food contact papers with improved barrier qualities and durability have been developed as a result of technological developments in paper manufacturing methods. Food contact paper is a thriving market segment in North America due in part to consumers' growing desire for convenience foods and online meal delivery services.

In conclusion, growing awareness of food safety, sustainability issues, and regulatory compliance are driving the market for food contact paper. In response to consumer expectations for packaging that is ecologically friendly, manufacturers are concentrating on creating novel solutions, such as food contact sheets that are recyclable and bio-based. Convenience foods, the growing use of online meal delivery services, and the expansion of the food packaging sector as a whole all contribute to the market's growth. The food contact paper market has a bright and sustainable future because of ongoing developments in materials and technologies and strict laws governing products that come into contact with food.

Key Developments:

| Year | Development |

| February 2024 | Through the expansion of EcoWicketBag production at its Szada, Hungary, facility, Mondi is able to further capitalize on the Group's integrated value chain, which encompasses internal paper manufacturing, coating, and converting. EcoWicketBags are constructed with FunctionalBarrier Paper 95/5 from Mondi, an incredibly durable kraft paper that can be tailored to have particular barrier and protective qualities to satisfy a range of product requirements. |

| October 2022 | Mondi's €400 million investment in a new paper machine at its Št?tí mill in the Czech Republic underscores its commitment to sustainable packaging and growth. This strategic move aligns with Mondi's broader €1 billion expansionary capital investment program aimed at accelerating its position in the market. |

| January 2022 | Paper carrier bags are increasingly being found in the dumpsters as plastic bags are gradually being phased out at the businesses. However, the paper bags are not designed to handle leftover waste from homes, which poses issues for garbage collectors, energy companies, and families alike. Four actors in Värmland are currently collaborating to find a solution to the problem of assigning a specific location for the paper bag in the waste system. |

Get in Touch

Interested in this topic? Contact our analysts for more details.

Latest Thought Articles

Top OSAT Companies Driving Semiconductor Assembly and Test Services Worldwide

Recently

EV Charging Stations Market Outlook: Smart Charging, Fast Charging, and Regional Expansion

Recently

Future of Corporate Wellness: Global Trends and Regional Outlook

Recently

Regional Breakdown of the Mechanical Keyboard Market: Who Leads and Why?

Recently