Source Measure Units are Crucial for Advanced Electronics Research

A Source Measure Unit (SMU) is a multi-functional electronic device that helps to make different electrical tests besides measurements. It can be utilized to infer the actual output current or voltage, while at the same time it can assess both parameters at the same time. This function allows researchers and engineers to find out important features of circuits under various conditions. SMUs are versatile for use in solar rooftop panel evaluations and examining battery efficiency as well as acting as a stage for new designs of electronic parts.

The fact that they are able to both manage as well as deal with either positive or negative voltage and current makes them stand out as one of the most multi-faceted elements in a range of industries such as semiconductor technology, nanoscience, solar energy, and battery research. Source measure units (SMUs) play an important significance in the recent electronics development and research progression. They will find the application in a great number of industries, including semiconductor, nanomaterial, photovoltaic, and advanced batteries, to precisely measure and control the electrical features of different devices accordingly. SMUs' ability to be adaptive is a key asset in promoting innovation in the rapidly moving and dynamic industry.

Global Production Trend

The number of SMU manufacturing worldwide is growing, and this happens owing to a significant number of reasons.

Rising demand in the electronics industry, especially where the manufacture of semiconductors, nanomaterials, photovoltaics, and advanced batteries are concerned, is the chief stimulant for this increased growth. These areas entail the precise regulation of electrical features in the multiple apparatuses that are indispensable for research and innovation.

Emphasis on precision with the devices getting smaller and smaller, the call for precise SMUs becomes louder every day. The producers, on their part, are coming up with units of high resolution and low noise levels so as to give the researchers even the highest resolution when studying complex electronic components. Integration and adaptability of modern SMUs are starting to integrate featuring several functions under a single unit. It broadens access for a single device and streamlines processes that are being done manually. Moreover, the manufacturers emphasize the agility factor by using modular designs that allow the end user to have the freedom to choose the components that best fit their research needs.

In Asia Pacific, the country with the largest growth in SMU is China. This trend is in line with the increasing electronics production in the area and increasing numbers of research and development projects. For instance, according to Shanghai Municipal Peoples Government published article in October 2023, it states that China’s consumer electronics retail market is expected to record a 4% growth rate with sales of about 2.2 trillion yuan, and it is predicted that the pace of the growth will increase to 5 percent at 2024.

Technological Developments In the pipeline there are directives to manufacturers to develop the SMU’s capabilities. In addition to advances in DSP technologies, UIs, and software for data processing, the world is expected to experience significant progress in the output of SMUs. To sum up, the world’s shipments of this product are increasingly high. Driven by the electronics industry growth and the demand for accurate electrical characterization, the manufacturers of a SMU pay attention to the development of new functionalities, usability and different region's growth as a way to meet the rising demand for this useful tool.

Source Measure Unit Use Case

SMU is one of the critical instruments that has a wide range of functions that are normally used in the electronic industry. Multiple industries depend on SMUs together with a wide range of system applications.

These application-specific static voltage converters perform a critical role in semiconductor research and development. They, genuinely, measure and supply voltage as well as current, which allows for an already existing analysis of the electrical behavior of the transistors, diodes, semiconductor devices, and other components under investigation. Therefore, this information has applications in enhancing device efficiency, exploring new materials, and maintaining a measure of consistency during production.

Nano-Electrical exploration smaller nanomaterials differ by the way they structurally behave in electrical environments requiring very specific characterization methods. Through SMU integrated with high-resolution functions, researchers can obtain the conductivity, resistance, deionization, and other electrical parameters of such sophisticated materials with ease. Data obtained is necessary to inculcate and fabricate nanomaterial-based devices for electronic, energy storage, and sensor applications.

Photovoltaic cells testing being the niche for the increase in productivity of the solar energy industry, SMUs become critically important in the research and development of new photovoltaic cells. They act as a tool to find current-voltage (I-V) curves that give the conversion solar to electricity ratio. Another vital function of both SMUs and TEAs is the ability to evaluate the long-term stability and outcomes of the solar cells under different operation circumstances.

The success of battery research and development is inseparable from steadiness testing devices (SMUs). They test, for instance, a battery's ability to absorb energy during charging and later release it during discharging, providing crucial information for improvement. Using voltage, current, and capacity values to the utmost extent, researchers can achieve advanced and improved battery designs by identifying any lag in performance levels.

Market Drivers and Dynamics

The growing SMU market is stimulated by a number of factors that affect the expanding complexity and miniaturization of electronic devices. The increasing prevalence of the electronics industry is the main cause driving the electronics Industry, especially in the sector of semiconductors, nanomaterials, photovoltaics, and advanced batteries, keeps on growing. Those fields explore highly accurate electric identification processes during the R&D of technological devices. Such a flourishing of these sectors naturally contributes to a demand for SMUs. For instance, in December 2023 Press Information Bureau published article it states that Micron's semiconductors project in Sanand, Gujarat is going very much on pace. Investment of US$ 2. 75 billion in a semiconductor manufacturing facility operated by Micon Industries Ltd., under the leadership of Prime Minister Shri Narendra Modi, has been approved by the Union Cabinet in June 2023.

Developments in electronic gadgets where the continued tendency of micronization of electronic components nudges more accurate measurement features. In order to meet this request, manufacturers increase the resolution of SMUs with reduced noise floor. Such developments make it possible to scrutinize the subtle workings of tiny machines and to ensure that those machines are operating properly.

The rise of the Asia Pacific market along with the rapid rise of China, the demand for SMUs in the Asia Pacific region, especially in China, is experiencing massive growth. This rate of growth reflects both the region's growing electronics production industry and a heightened allocation of resources to R&D activities. The Asia Pacific area is a major market for the Singaporean manufacturers.

Technological advancements and future outlooks the source measure unit market is driven by innovation all the time. Digital signal processing developments along with interface improvement and smooth data analysis software integration offer additional grounds for SMU’s feasibility. In this way, these means improve convenience, increase work efficiency, and extend the power of data analysis to researchers. For instance, in July 2023 Keysight Technologies raised the overall testing bar of chips using their new high-density multipurpose current source. It's a powerhouse and channels multiplexing into a compact and dynamic design, facilitating further semiconductor characterizations. Researchers will be in a position to test a greater number of devices undergoing simulative conditions, which will lead to a progressive process of innovation with regard to the technology that will keep on improving.

The market of the source measure unit is strongly related to the constant progress of electronics and its impact in R&D activities. Alongside with the surge in the demand for high-level electronic devices, the demand for complex measurement equipment like SMUs too will grow. Manufacturers are currently coming up with new techniques and are modifying their methods themselves so as to cater to the evolving needs of the market.

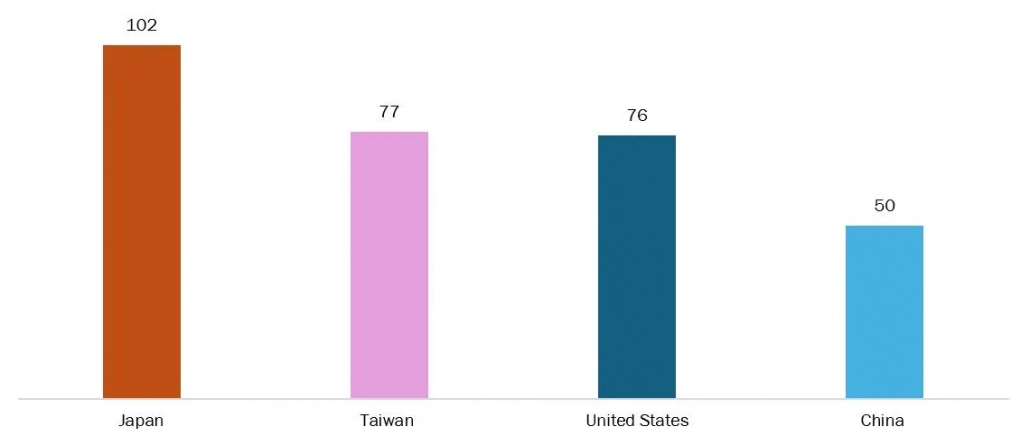

The fabrication plants of such facilities provide the necessary impetus needed for the revolution in chip design and manufacturing. The more this market segment grows in terms of producing complicated semiconductors, the greater becomes the demand for exact testing. This moves up the demand for feature rich SMUs which then help maintain the quality control, thereby, increase the size of the market for source measure units. Based on a 2022 data relative to the region, it was recorded that Japan has the highest number of fabs at 102 fabrication plants followed by Taiwan with 77 fabs, the United States with 76 fabs, and China with 50 fabs.

Figure 1: Semiconductor Fabrication Plants by Countries (2022)

Source: World Population Review

Market Challenges

The SMU market is grappling with a tough balancing task. Despite the fact that the market for SMUs with high conformity is in great demand, the competitive cost of maintenance can be complicated. Additionally, manufacturers contend with continuous frequent innovation in electronics, which necessitates them to remain on the cutting edge in terms of the devices they manufacture. Along with these challenges, some disorder in the supply chain could be a further issue for the new source measure unit market.

Emerging Opportunities and Innovations

The source measure unit (SMU) business offers a lot of promising prospects. As the miniaturization trend in electronics becomes noticeable, SMUs need to be more precise all the time. In turn, manufacturers produce multichannel units with high resolution. Cloud-based solutions start coming up, which support remote research environments. While this, advanced materials such as nanomaterials and the study of organic electronics are opening up new approaches for SMU application. Through innovation in user interface, data analysis integration, and also modular designs, SMU manufacturers can support researchers to ensure the growth of electronic technology in the coming years.

Key Developments

In February 2024: The ITECH IT2800 is a combined source, the digital and pulse generator along with the meter that occupies a small unit. It provides high-precision voltage and current measurement that goes well with different electronic device testing in the research, development, and production environments.

At last, concluding that the source measure unit market is anticipated to have various innovations and growth opportunities over the forecast period. The market is driven by the increasing prevalence of the electronic industry and Developments in electronic gadgets where the continued tendency of micronization of electronic components nudges more accurate measurement features. There are various challenges to be faced such as the adoption to continuous innovations and supply chain disruptions. Therefore, the industry is projected to maximize technological advancements and innovations to mee the needs of a growing global demand for the source measure unit market.

Source: World Population Review

Market Challenges

The SMU market is grappling with a tough balancing task. Despite the fact that the market for SMUs with high conformity is in great demand, the competitive cost of maintenance can be complicated. Additionally, manufacturers contend with continuous frequent innovation in electronics, which necessitates them to remain on the cutting edge in terms of the devices they manufacture. Along with these challenges, some disorder in the supply chain could be a further issue for the new source measure unit market.

Emerging Opportunities and Innovations

The source measure unit (SMU) business offers a lot of promising prospects. As the miniaturization trend in electronics becomes noticeable, SMUs need to be more precise all the time. In turn, manufacturers produce multichannel units with high resolution. Cloud-based solutions start coming up, which support remote research environments. While this, advanced materials such as nanomaterials and the study of organic electronics are opening up new approaches for SMU application. Through innovation in user interface, data analysis integration, and also modular designs, SMU manufacturers can support researchers to ensure the growth of electronic technology in the coming years.

Key Developments

In February 2024: The ITECH IT2800 is a combined source, the digital and pulse generator along with the meter that occupies a small unit. It provides high-precision voltage and current measurement that goes well with different electronic device testing in the research, development, and production environments.

At last, concluding that the source measure unit market is anticipated to have various innovations and growth opportunities over the forecast period. The market is driven by the increasing prevalence of the electronic industry and Developments in electronic gadgets where the continued tendency of micronization of electronic components nudges more accurate measurement features. There are various challenges to be faced such as the adoption to continuous innovations and supply chain disruptions. Therefore, the industry is projected to maximize technological advancements and innovations to mee the needs of a growing global demand for the source measure unit market.

| Subscribe Us |

Get in Touch

Interested in this topic? Contact our analysts for more details.

Latest Blogs

Solar Control Window Films Market expected to reach USD 1,224.951 million by 2030

RecentlyTop Companies Leading the Silicon-Based Capacitor Revolution

Recently

The Role of Chemical Blowing Agents in Sustainable Foaming Solutions

Recently

Top 10 Emerging Beverages Set to Dominate the Market in the Coming Years

Recently