Understanding Gear Pumps: Working Principles, Applications, and Benefits

The gear pumps are used for transferring liquids across different industrial applications and can be used to transfer different types of liquids that have different viscosity and need to be maintained at different temperatures using these technologically advanced gear pumps. These gear pumps can transfer liquids from the inlet of the pump to the outlet of the pump using two or more than two gears placed inside the pump that can trap the liquid between the rotating gears and in the process of doing that the pump can push the liquid towards the outlet of the gear pump to complete the transfer efficiently.

Growth Drivers:

The factors that are contributing to the growth of the gear pumps market in the industry are the growth in the demand for them to be used in hydraulic pump systems across different industrial applications such as the food & beverage industry that uses these gear pumps for transfer of different liquid food products like sauce and syrups and across different industrial applications such as manufacturing units where all processes are automated and the automatic hydraulic pumps are used for smooth and efficient transfer of liquids and similarly in the automotive industry coupled with construction sites they use hydraulic pumps that are important to provide good productivity and smooth functioning of production process.

Moreover, there is a significant improvement in the gear pump technology that makes it more compatible with other liquids and widens the end-use applications for them such as the food & beverage industry, chemical processing industry, and oil & gas industry where the need for liquid transfer is important in the production process and hence, is predicted to drive the demand for gear pumps with their growth.

Another factor fueling the demand for gear pumps in the market is industrial automation across different manufacturing and production units. This has led to the adoption of automated hydraulic systems across different industry verticals that can provide better efficiency and productivity to the manufacturers and can be used in various industries where automation is being adopted at a fast pace such as the aerospace, marine, and automotive industry.

Applications of gear pumps:

The automatic hydraulic pump that has gear pumps in it provides seamless functioning and operation of the production process in these automated industries which has led to its wide adoption in these industries. Also, these automated hydraulic pumps are more versatile and can maintain different temperatures and viscosity according to the need of the user and the liquid it is being used for transferring, therefore, the rise in industrial automation is predicted to grow the gear pump market.

These gear pumps are necessary and cater to different applications of different end-users that provide smooth liquid transfer using these automated and advanced hydraulic pumps integrated with gear pumps to increase the productivity of the manufacturing or industrial applications such as drilling operations, crude oil pumping, and hydraulic power units. These significant advancements in the technology of hydraulic pumps have led to an increase in productivity, efficiency, and smooth functioning of the production process at these different industry verticals. Also, the growing demand for energy across the globe has led to a wide range of operations of oil & gas manufacturing that need gear pumps or hydraulic pumps that use them for efficient and productive operation which in turn will drive the demand for gear pumps in the market.

The is a significant rise in the infrastructures for the chemical processing industry that need gear pumps to handle different types of liquid chemicals with unique properties easily with the growth in demand for its wide range of applications across different industry verticals such as the need for petrochemicals or petroleum products for energy resources and other petroleum-related products, industrial gases such as the natural gas which is used as an energy resource across the globe in automotive and several other industries, and specialized chemicals for different industrial use has increased the need for gear pumps which in turn is growing the production of these gear pumps in the market.

The gear pumps are one of the important parts of the production process in the chemical processing industry as these gear pumps are required to transfer liquid chemicals at certain temperatures that need to be maintained throughout the transfer process with precision and efficiency that can only be done using these gear pumps. These chemical transfers done using gear pumps have other requirements while in the process of transferring such as dosing, metering, and mixing of liquid chemicals that can be completed with technological advancements and innovations in the gear pump device which drives the demand for gear pumps in the market.

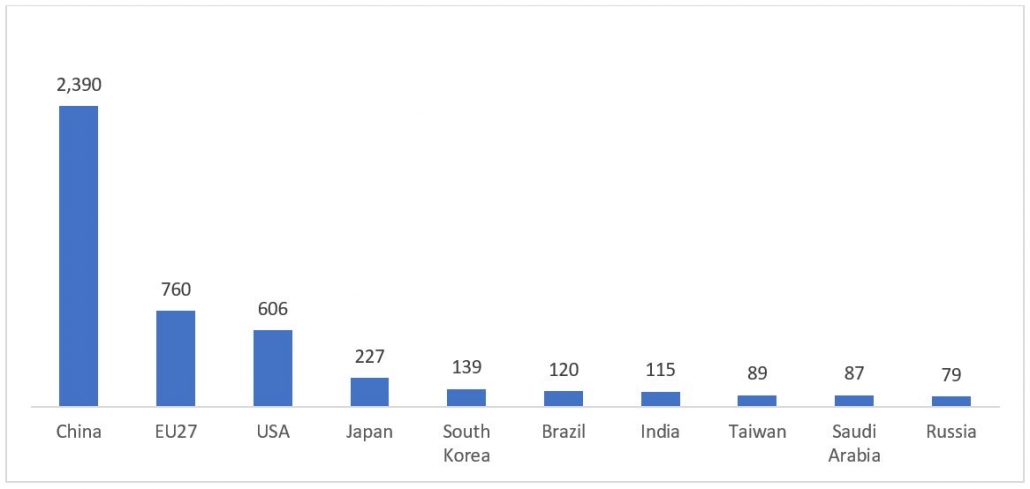

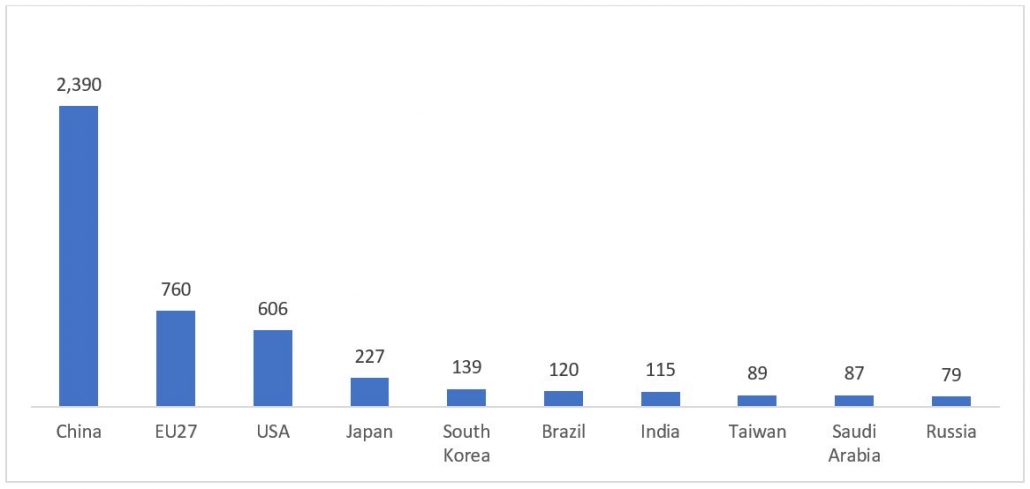

In 2022, the EU27 chemical industry—which includes consumer, specialty, and base chemicals—employed 1.2 million people and supply a wide range of industries, according to Cefic Chemdata International. Top 10 countries with the highest chemical sales were China (2390 billion Euro), EU27(760 billion Euro), the USA (606 billion Euro), Japan (227 billion Euro), South Korea (139 billion Euro), Brazil (120 billion Euro), India (115 billion Euro), Taiwan (89 billion Euro), Saudi Arabia (87 billion Euro), and Russia (79 billion Euro).

Figure 1: World Chemical Sales (Top 10 Countries), in € Billion, in 2022

Source: Cefic Chemdata International

The growth in the food & beverage industry is prominent across the globe and is growing rapidly with the growing global population. The food & beverage industry includes packaged foods and beverages which are growing in demand as it is convenient and easy for customers to order and eat these packaged foods. The gear pumps play a crucial role in the production process of this packaged food and beverage industry to transfer and handle different types of liquid products like sauces, syrups, milk, and other dairy products.

The gear pumps make it easy and convenient for manufacturers to perform different operations like dosing, filling, and mixing of these liquid products using gear pumps that further increase its demand in the food & beverage industry. Also, these gear pumps preserve food integrity and handle the products with hygiene which makes them appealing to food and beverage industry manufacturers and is adopted by them which in turn grows the gear pump market.

Types of Gear Pumps:

The gear pump industry is divided into two types which are internal gear pumps and external gear pumps each has its unique abilities and functions in the wide range of applications in different end-user industries to cater to their different needs as internal gear pumps are used to handle high-viscosity liquids and are majorly efficient in the metering of different kinds of liquids while transferring them from inlet to the outlet of the gear pump. These gear pumps are highly efficient and smooth for high-pressure liquids and are widely used in different industrial applications including hydraulic and lubrication systems.

On the other hand, in the external gear pumps there are two or more gears that are rotating and are working together to pump liquids to transfer them across from the inlet to the outlet of the gear pump. These pumps are known for their simplicity and compact size and are widely used in fuel transfer and chemical processing in the industry which further propels the growth of gear pumps in the market over the forecast period.

Regional growth prospects:

The growth is projected to be prominent in the Asia Pacific region for the gear pump market which is driven by several factors such as the fast industrialization and urbanization across different countries in the region especially in China, India, and Japan which are considered manufacturing hubs and China being one of the largest production hubs in the world is expected to drive the demand for gear pumps in the Asia Pacific region. There are different applications of gear pumps in industries like food & beverages and oil & gas that are rapidly growing in demand in the region which is expected to positively impact the market growth of gear pumps in the Asia Pacific region.

In addition, the need for gear pumps in the agriculture industry for efficient farming and good yield by improving irrigation systems coupled with the massive growth of automotive production in the Asia Pacific region with key players like Honda, Toyota, and TATA Motors that manufacture vehicles need gear pumps to provide efficient and large-scale vehicle production

Moreover, the significant investments made by government and private organizations to automate the production process and improve the existing technology in manufacturing with growing economies and improving GDPs of several countries in the Asia Pacific region are contributing to grow the gear pumps market in the Asia Pacific region over the forecast period.

At last, concluding that the gear pumps market is predicted to have several innovations and growth opportunities over the forecast period with growth in different industry verticals like the food & beverage processing industry. These sectors drive market demand because they depend on gear pumps for effective fluid handling, transfer, and processing applications. The market is also growing as a result of technical developments that enhance performance, longevity, and material compatibility. A strong rise in infrastructure and industrialization is driving regions such as Asia Pacific. Overall, the gear pump market is expected to continue growing and innovating in the upcoming years due to the growing demand for dependable and effective fluid-handling solutions across a variety of sectors.

Key Developments:

Source: Cefic Chemdata International

The growth in the food & beverage industry is prominent across the globe and is growing rapidly with the growing global population. The food & beverage industry includes packaged foods and beverages which are growing in demand as it is convenient and easy for customers to order and eat these packaged foods. The gear pumps play a crucial role in the production process of this packaged food and beverage industry to transfer and handle different types of liquid products like sauces, syrups, milk, and other dairy products.

The gear pumps make it easy and convenient for manufacturers to perform different operations like dosing, filling, and mixing of these liquid products using gear pumps that further increase its demand in the food & beverage industry. Also, these gear pumps preserve food integrity and handle the products with hygiene which makes them appealing to food and beverage industry manufacturers and is adopted by them which in turn grows the gear pump market.

Types of Gear Pumps:

The gear pump industry is divided into two types which are internal gear pumps and external gear pumps each has its unique abilities and functions in the wide range of applications in different end-user industries to cater to their different needs as internal gear pumps are used to handle high-viscosity liquids and are majorly efficient in the metering of different kinds of liquids while transferring them from inlet to the outlet of the gear pump. These gear pumps are highly efficient and smooth for high-pressure liquids and are widely used in different industrial applications including hydraulic and lubrication systems.

On the other hand, in the external gear pumps there are two or more gears that are rotating and are working together to pump liquids to transfer them across from the inlet to the outlet of the gear pump. These pumps are known for their simplicity and compact size and are widely used in fuel transfer and chemical processing in the industry which further propels the growth of gear pumps in the market over the forecast period.

Regional growth prospects:

The growth is projected to be prominent in the Asia Pacific region for the gear pump market which is driven by several factors such as the fast industrialization and urbanization across different countries in the region especially in China, India, and Japan which are considered manufacturing hubs and China being one of the largest production hubs in the world is expected to drive the demand for gear pumps in the Asia Pacific region. There are different applications of gear pumps in industries like food & beverages and oil & gas that are rapidly growing in demand in the region which is expected to positively impact the market growth of gear pumps in the Asia Pacific region.

In addition, the need for gear pumps in the agriculture industry for efficient farming and good yield by improving irrigation systems coupled with the massive growth of automotive production in the Asia Pacific region with key players like Honda, Toyota, and TATA Motors that manufacture vehicles need gear pumps to provide efficient and large-scale vehicle production

Moreover, the significant investments made by government and private organizations to automate the production process and improve the existing technology in manufacturing with growing economies and improving GDPs of several countries in the Asia Pacific region are contributing to grow the gear pumps market in the Asia Pacific region over the forecast period.

At last, concluding that the gear pumps market is predicted to have several innovations and growth opportunities over the forecast period with growth in different industry verticals like the food & beverage processing industry. These sectors drive market demand because they depend on gear pumps for effective fluid handling, transfer, and processing applications. The market is also growing as a result of technical developments that enhance performance, longevity, and material compatibility. A strong rise in infrastructure and industrialization is driving regions such as Asia Pacific. Overall, the gear pump market is expected to continue growing and innovating in the upcoming years due to the growing demand for dependable and effective fluid-handling solutions across a variety of sectors.

Key Developments:

Source: Cefic Chemdata International

The growth in the food & beverage industry is prominent across the globe and is growing rapidly with the growing global population. The food & beverage industry includes packaged foods and beverages which are growing in demand as it is convenient and easy for customers to order and eat these packaged foods. The gear pumps play a crucial role in the production process of this packaged food and beverage industry to transfer and handle different types of liquid products like sauces, syrups, milk, and other dairy products.

The gear pumps make it easy and convenient for manufacturers to perform different operations like dosing, filling, and mixing of these liquid products using gear pumps that further increase its demand in the food & beverage industry. Also, these gear pumps preserve food integrity and handle the products with hygiene which makes them appealing to food and beverage industry manufacturers and is adopted by them which in turn grows the gear pump market.

Types of Gear Pumps:

The gear pump industry is divided into two types which are internal gear pumps and external gear pumps each has its unique abilities and functions in the wide range of applications in different end-user industries to cater to their different needs as internal gear pumps are used to handle high-viscosity liquids and are majorly efficient in the metering of different kinds of liquids while transferring them from inlet to the outlet of the gear pump. These gear pumps are highly efficient and smooth for high-pressure liquids and are widely used in different industrial applications including hydraulic and lubrication systems.

On the other hand, in the external gear pumps there are two or more gears that are rotating and are working together to pump liquids to transfer them across from the inlet to the outlet of the gear pump. These pumps are known for their simplicity and compact size and are widely used in fuel transfer and chemical processing in the industry which further propels the growth of gear pumps in the market over the forecast period.

Regional growth prospects:

The growth is projected to be prominent in the Asia Pacific region for the gear pump market which is driven by several factors such as the fast industrialization and urbanization across different countries in the region especially in China, India, and Japan which are considered manufacturing hubs and China being one of the largest production hubs in the world is expected to drive the demand for gear pumps in the Asia Pacific region. There are different applications of gear pumps in industries like food & beverages and oil & gas that are rapidly growing in demand in the region which is expected to positively impact the market growth of gear pumps in the Asia Pacific region.

In addition, the need for gear pumps in the agriculture industry for efficient farming and good yield by improving irrigation systems coupled with the massive growth of automotive production in the Asia Pacific region with key players like Honda, Toyota, and TATA Motors that manufacture vehicles need gear pumps to provide efficient and large-scale vehicle production

Moreover, the significant investments made by government and private organizations to automate the production process and improve the existing technology in manufacturing with growing economies and improving GDPs of several countries in the Asia Pacific region are contributing to grow the gear pumps market in the Asia Pacific region over the forecast period.

At last, concluding that the gear pumps market is predicted to have several innovations and growth opportunities over the forecast period with growth in different industry verticals like the food & beverage processing industry. These sectors drive market demand because they depend on gear pumps for effective fluid handling, transfer, and processing applications. The market is also growing as a result of technical developments that enhance performance, longevity, and material compatibility. A strong rise in infrastructure and industrialization is driving regions such as Asia Pacific. Overall, the gear pump market is expected to continue growing and innovating in the upcoming years due to the growing demand for dependable and effective fluid-handling solutions across a variety of sectors.

Key Developments:

Source: Cefic Chemdata International

The growth in the food & beverage industry is prominent across the globe and is growing rapidly with the growing global population. The food & beverage industry includes packaged foods and beverages which are growing in demand as it is convenient and easy for customers to order and eat these packaged foods. The gear pumps play a crucial role in the production process of this packaged food and beverage industry to transfer and handle different types of liquid products like sauces, syrups, milk, and other dairy products.

The gear pumps make it easy and convenient for manufacturers to perform different operations like dosing, filling, and mixing of these liquid products using gear pumps that further increase its demand in the food & beverage industry. Also, these gear pumps preserve food integrity and handle the products with hygiene which makes them appealing to food and beverage industry manufacturers and is adopted by them which in turn grows the gear pump market.

Types of Gear Pumps:

The gear pump industry is divided into two types which are internal gear pumps and external gear pumps each has its unique abilities and functions in the wide range of applications in different end-user industries to cater to their different needs as internal gear pumps are used to handle high-viscosity liquids and are majorly efficient in the metering of different kinds of liquids while transferring them from inlet to the outlet of the gear pump. These gear pumps are highly efficient and smooth for high-pressure liquids and are widely used in different industrial applications including hydraulic and lubrication systems.

On the other hand, in the external gear pumps there are two or more gears that are rotating and are working together to pump liquids to transfer them across from the inlet to the outlet of the gear pump. These pumps are known for their simplicity and compact size and are widely used in fuel transfer and chemical processing in the industry which further propels the growth of gear pumps in the market over the forecast period.

Regional growth prospects:

The growth is projected to be prominent in the Asia Pacific region for the gear pump market which is driven by several factors such as the fast industrialization and urbanization across different countries in the region especially in China, India, and Japan which are considered manufacturing hubs and China being one of the largest production hubs in the world is expected to drive the demand for gear pumps in the Asia Pacific region. There are different applications of gear pumps in industries like food & beverages and oil & gas that are rapidly growing in demand in the region which is expected to positively impact the market growth of gear pumps in the Asia Pacific region.

In addition, the need for gear pumps in the agriculture industry for efficient farming and good yield by improving irrigation systems coupled with the massive growth of automotive production in the Asia Pacific region with key players like Honda, Toyota, and TATA Motors that manufacture vehicles need gear pumps to provide efficient and large-scale vehicle production

Moreover, the significant investments made by government and private organizations to automate the production process and improve the existing technology in manufacturing with growing economies and improving GDPs of several countries in the Asia Pacific region are contributing to grow the gear pumps market in the Asia Pacific region over the forecast period.

At last, concluding that the gear pumps market is predicted to have several innovations and growth opportunities over the forecast period with growth in different industry verticals like the food & beverage processing industry. These sectors drive market demand because they depend on gear pumps for effective fluid handling, transfer, and processing applications. The market is also growing as a result of technical developments that enhance performance, longevity, and material compatibility. A strong rise in infrastructure and industrialization is driving regions such as Asia Pacific. Overall, the gear pump market is expected to continue growing and innovating in the upcoming years due to the growing demand for dependable and effective fluid-handling solutions across a variety of sectors.

Key Developments:

- In January 2024, Performance curve documents for each of the internal gear pump models were released by Blackmer. The following items were covered by these documents: V Series Asphalt Gear Pump, E Series Magnetic Drive Gear Pump, and G Series Internal Gear Pump. For every size gear pump, these performance curve documents include both driving power and flow rate curves. They also offer curves for up to seven distinct viscosity levels and for various pump building materials, such as iron steel and stainless steel (where applicable).

- In December 2022, Dover announced the completion of its purchase of Witte Pumps & Technology GmbH ("Witte"), a precision gear pump manufacturer. Witte was integrated into Dover's Pumps & Process Solutions sector as a business unit called Maag.

Get in Touch

Interested in this topic? Contact our analysts for more details.

Latest Thought Articles

Top OSAT Companies Driving Semiconductor Assembly and Test Services Worldwide

Recently

EV Charging Stations Market Outlook: Smart Charging, Fast Charging, and Regional Expansion

Recently

Future of Corporate Wellness: Global Trends and Regional Outlook

Recently

Regional Breakdown of the Mechanical Keyboard Market: Who Leads and Why?

Recently