Top 10 Industrial Chemicals: Essential Compounds Driving Modern Industry

How Industrial Chemicals Power Modern Manufacturing and Daily Life

Industrial chemicals are a driving force behind the modern industrial world. They serve as essential components in a wide range of manufacturing processes and play a crucial role in enabling innovation. These chemicals ensure efficient production workflows and support the development of advanced manufacturing technologies. From cutting-edge semiconductor chips with 3nm architecture to anti-corrosion coatings and high-efficiency fertilizers used in agriculture, industrial chemicals are at the core of these advancements.

These chemicals are integrated into nearly every aspect of modern life. They are found in pharmaceuticals, household paints, smartphones, vehicles, and even the fabrics of the clothes we wear. Industrial chemicals help products last longer, perform better, and meet the high-performance standards expected today. Simply put, they are the foundation of durable, high-quality, and efficient products across every major industry.

Get In-Depth Analysis of the Chemicals Market

This article covers the fundamentals. Our full market reports provide the granular data and strategic insights you need to make informed business decisions.- ? Detailed Market Size & Growth Forecasts

- ? Competitive Landscape & Key Player Analysis

- ? Regional Breakdowns & Emerging Trends

Top 10 Industrial Chemicals:

1) Sulfuric Acid (H2SO4)

2) Nitrogen (N2)

3) Ethylene (C2H4)

4) Oxygen (O2)

5) Propylene (C3H6)

6) Chlorine (Cl2)

7) Ethylene Dichloride (C2H2Cl2)

8) Phosphoric Acid (H3PO4)

9) Ammonia (NH3)

10) Sodium Hydroxide (NaOH)

1. Sulfuric Acid (H2SO4)

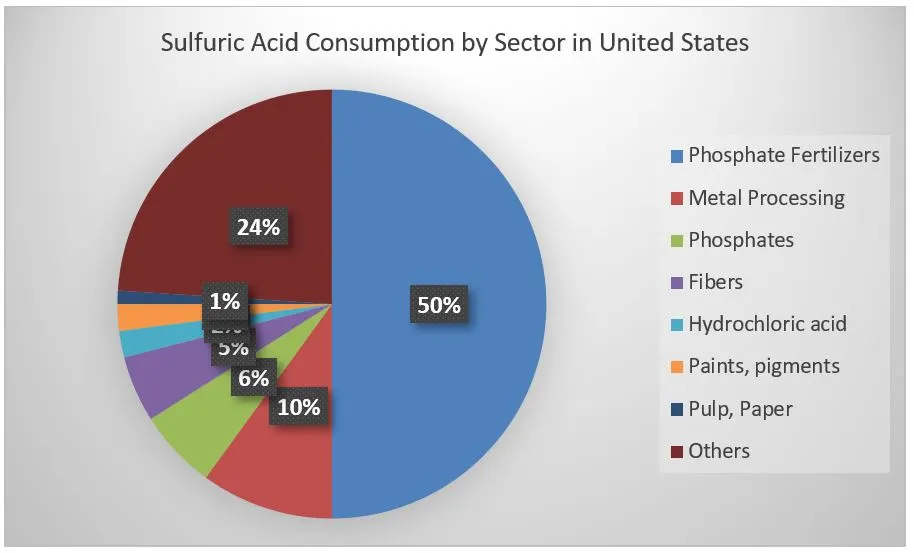

Sulfuric acid is the most consumed industrial chemical in the world. The agriculture sector consumes the most sulfuric acid to produce fertilizers. It is also used to produce detergents, lead-acid automotive batteries, dyes, pigments, explosives, and other chemicals like hydrochloric acid (HCL).

Sulfuric acid is used in other important industrial processes, such as etching and cleaning semiconductor chips and printed circuit boards. It is also used in petroleum refining and acts as a reactant in rayon and nitroglycerin.

Data-Driven Insights on the Sulfuric Acid Market

Understand the key drivers and market dynamics of the world's most consumed industrial chemical.The demand for sulfuric acid is expected to grow in industries such as the automotive, electrical and electronics, and fertilizer industries.

The above-mentioned applications make sulfuric acid one of the most consumed industrial chemicals.

The United States is one of the largest sulfuric acid producers; 7.6 million tons of elemental sulfur is produced in the United States each year, of which 90% is consumed in sulfuric acid production.

2. Nitrogen (N2)

Nitrogen is a colorless, odorless inert gas and constitutes 78% (by volume) of the air we breathe. Due to its inert properties, it is commonly used as a blanketing gas that protects oxygen-sensitive products from oxidizing by covering the product.

In industrial scenarios, liquid nitrogen is highly used in various applications, such as the production of steel and other metals, as a coolant for scientific experiments, reactor cooling, and flour and dough cooling in the food industry.

The food industry is one of the largest nitrogen consumers in gas and liquid form. Nitrogen gas is used in food packaging to increase the shelf life of packaged food, and liquid nitrogen is used in refrigerated trucks to keep food fresh and avoid food contact with the air.

In the healthcare industry, liquid nitrogen is used to freeze blood samples and tissues. Several liquid nitrogen products are made for tissue relaxing during strain or internal wounds.

3. Ethylene (C2H4)

Ethylene is a petrochemical produced in large volumes globally. Nearly 95% of the annual commercial ethylene is produced by steam cracking of petroleum hydrocarbons. Various feedstocks, such as propane, ethane, butane, gas oils, and naphtha, are used to produce ethylene. Naphtha is a key raw material in ethylene production, with nearly 80% of the ethylene produced in the US, Europe, and Japan by naphtha alone. There has been a growing demand for bio-ethylene with a focus on reducing greenhouse gas (GHG) emissions.

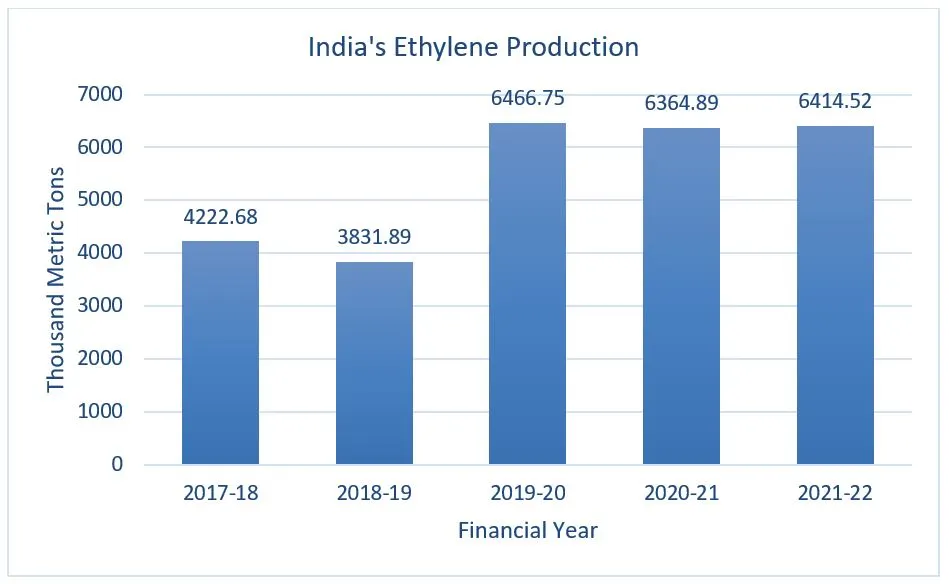

India’s ethylene production is growing at a CAGR of 11.04% over the past five years. Most of the ethylene produced goes into the production of high-density polyethylene (HDPE), linear low-density polyethylene (LLDPE), and low-density polyethylene (LDPE). In 2022, polyethylene production consumed 84.38% of the ethylene in India. LLDPE accounts for the largest production volume of 3,497 thousand metric tons or 54.52% share of ethylene consumption.

While most commercially produced ethylene is used to produce polymers and industrial chemicals, a small amount is utilized in the controlled ripening of citrus fruits, tomatoes, bananas, and many other fruits and vegetables.

Ethylene is also used to produce ethylene glycol, polystyrene for packaging and insulation, ethanol for industrial use, polyester, and synthetic rubber, among other things.

4. Oxygen (O2)

Oxygen in industries is mainly utilized in the combustion process. Commercially produced oxygen is used in oxyacetylene and oxyhydrogen welding torches.

Oxygen is also used in chemical industries to break down hydrocarbons into smaller hydrocarbons like ethylene, propylene, and acetylene, which are later utilized in the production of paints, plastics, and other products.

Rockets are fueled by liquid hydrogen and liquid oxygen cryogenic propellants. The oxygen tank used to launch a space shuttle contains around 550,000 liters of liquid oxygen.

Other industries that use oxygen gas or liquid oxygen include medical, paper and pulp, water treatment, metal production, glass, and the chemical industry.

Air Liquide has the largest oxygen plant in the world and is a global leader in producing industrial gases like oxygen, nitrogen, and hydrogen.

Russia, France, South Africa, India, the United States, and China are some of the major oxygen producers globally.

5. Propylene (C3H6)

Propylene, also known as propene, is a highly versatile hydrocarbon with the chemical formula C?H?. This colorless gas has a faint petroleum-like odor and is highly flammable. It is primarily produced through catalytic or thermal cracking of hydrocarbons and often emerges as a byproduct during petroleum refining and natural gas processing. Propylene serves as a crucial intermediate in the synthesis of numerous industrial chemicals and materials.

One of the primary uses of propylene is in the production of polypropylene, a widely utilized thermoplastic polymer. Known for its durability, chemical resistance, and flexibility, polypropylene is essential in manufacturing packaging materials, automotive parts, textiles, and everyday consumer products. Approximately two-thirds of the global supply of propylene is dedicated to making polypropylene.

Beyond polypropylene, propylene is a vital raw material for creating several other key chemicals, including propylene oxide, acrylonitrile, cumene, and acrylic acid. Propylene oxide is used to produce polyurethanes, which are found in furniture, car components, and insulation. Acrylonitrile is essential for manufacturing acrylic fibers for textiles, plastic components in electronics and vehicles, and synthetic rubber. Cumene is processed into phenol and acetone, both used in producing adhesives, polymers, and resins.

Propylene also plays a major role in the production of isopropyl alcohol, a common solvent used in pharmaceuticals, personal care products, and household cleaners. Additionally, propylene is used to manufacture plasticizer alcohols, which are found in coatings, flexible plastics, and adhesives. Its application extends to surface coatings, sealants, and superabsorbent polymers used in hygiene products like diapers and sanitary pads—highlighting its widespread industrial significance.

6. Chlorine (Cl2)

Chlorine (Cl2) is one of the top-consumed chemicals in the world. It is mainly produced through the electrolysis of sodium chloride brine. A yellow-green gas known for its pungent smell, chlorine is a key ingredient in various industrial applications due to its high reactivity and oxidizing potential.

Its density is approximately 2.5 times greater than air, and owing to this reason, it remains close to the ground. Even though it's not flammable, chlorine can produce explosive compounds with acetylene and ammonia, requiring careful handling and storage.

Chlorine is extensively used in water treatment and disinfection processes. It is necessary for treating sewage and industrial waste and cleaning drinking water to protect public health and the environment. Its function in sanitation also includes swimming pools, which use chlorine and its derivatives to keep the water clean.

Chlorine is widely used in the chemical industry to produce various goods. Because of its strong oxidizing ability, chlorine is a vital component used in producing industrial bleaches and disinfectants. It is also essential for synthesizing insecticides, chlorides, and chlorinated solvents. It is also used in the synthesis of polymers, synthetic rubbers, and refrigerants.

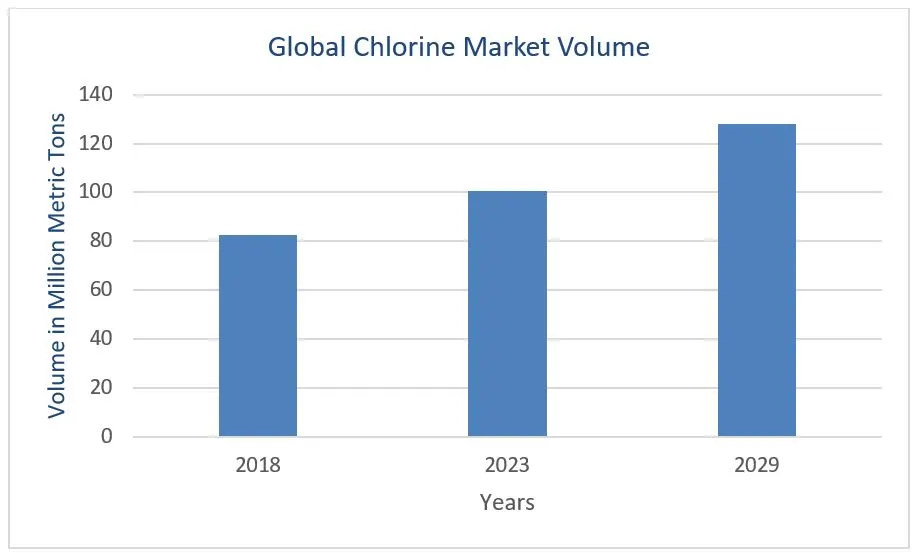

Chlorine is used in industrial processes to whiten and purify paper and textiles, thereby improving their appearance and quality. It is also dissolved in water in household cleaning solutions, which makes it an important chemical for daily sanitation and hygiene. It is an important chemical that is used in both industrial and household applications. Chlorine production has observed significant growth in India, with 1900 thousand metric tons in 2018 and 2499 thousand metric tons in 2022. The global demand for chlorine is likely to grow at a CAGR of 4.1% by 2030.

7. Ethylene Dichloride (C2H2Cl2)

Ethylene dichloride (EDC), or 1,2-dichloroethane, is an oily, colorless liquid with a sweet smell that is mainly produced when ethylene is chlorinated. EDC is a key raw material for producing vinyl chloride monomer (VCM). PVC is also produced from EDC, which is well known for its toughness and adaptability, and is crucial to the building sector.

In addition to PVC, ethylene dichloride is essential for producing polystyrene, a valuable synthetic polymer. A wide range of consumer goods and packaging materials are made with polystyrene. Applications for EDC include the creation of specific dry-cleaning fluids that use their solvent qualities to efficiently clean textiles without the need for water. Because of this, EDC is essential to preserving the hygiene and aesthetics of textiles.

EDC makes shower curtains, flooring, and synthetic rubber possible. It is also used to create synthetic rubber, which is essential for making a variety of goods, including industrial gaskets and car tires.

Considering its wide range of industrial uses, it is categorized as a human carcinogen. Prolonged exposure to elevated levels can cause major health problems, such as damage to the kidneys and liver. Thus, to reduce potential risks and guarantee the safety of both employees and the environment, stringent safety procedures and legal requirements are necessary during its manufacturing, storage, and usage.

8. Phosphoric Acid (H3PO4)

Phosphoric acid is made from phosphate rock by wet or thermal processes. Nearly 80% of the global phosphoric acid is produced by wet processes.

Phosphoric acid (H3PO4) is used for many consumer, industrial, and agricultural purposes. One of the major applications of phosphoric acid is the phosphate salts used in fertilizers. This acid is present in around 8% of the fertilizers used in the agricultural sector, making it one of the most important ingredients for fostering plant development and growing crop yields. Furthermore, phosphoric acid is frequently used in animal feed, offering vital nutrients to cattle and chickens and helping promote their well-being and efficiency.

Explore the Phosphoric Acid & Ammonia Markets

Get a comprehensive view of the market drivers, supply chain, and growth forecasts for these interconnected industries.In the Pharmaceutical industry, phosphoric acid is used as an intermediate for various medicines like antinausea medicines, mouthwash products, and teeth whitening. Dentists use phosphoric acid as a dental procedure to clean teeth.

Phosphoric acid use in the food industry is quite popular. It is used in various products like cheese, processed meat, jams, cereal bars, and cold drinks, among others.

Phosphoric acid is widely used in the rust-removal process of steel, iron, and other metals. The rust that covers metal is transformed into a black compound once it comes in contact with phosphoric acid, and can be wiped easily.

Owing to its versatility, phosphoric acid demand is growing globally. East Asia is the largest producer of phosphoric acid, with around 30 billion tons produced in 2022.

9. Ammonia (NH3)

Ammonia is one of the most commonly produced industrial chemicals globally. It is an essential biological ingredient that acts as a precursor for ammonia acid, and nucleotide synthesis. Ammonia is part of the nitrogen cycle and is produced in soil from bacterial processes. In its pure form, it is known as anhydrous ammonia and is hygroscopic in nature (i.e., it rapidly absorbs moisture from the environment).

More than 70% of the commercially produced ammonia is used as fertilizers. It is also used as refrigerant gases, for purifying water supplies, and for manufacturing products like explosives, plastics, textiles, dyes, pesticides, and other chemicals.

It is used in the production of nitric acid, certain dyes, sulfa drugs, cosmetics, vitamins, and synthetic textiles like rayon and nylon, among other things.

China is the largest producer of ammonia, with nearly 15% share, followed by Russia, the United States, India, and Brazil. In 2021, there were 490 active ammonia plants in more than 64 countries, with an annual production of around 185 million metric tons.

The companies with the largest production capacities are BASF SE, CF Industries Holdings Inc., CSBP Limited, EuroChem, Group DF, Gujarat State Fertilizer & Chemicals Limited, IFFCO, Koch Industries Inc., Nutrien, OCI Nitrogen, PJSC Togliattiazot, PT Pupuk Srivijaya Palembang (Pusri), Qatar Fertiliser Company, Rashtriya Chemicals and Fertilizers Limited, SABIC, and Yara.

10. Sodium Hydroxide (NaOH)

Sodium Hydroxide, commonly known as caustic soda, is a strong base that finds applications across various industries due to its highly reactive and versatile nature. It is used in the petroleum industry to increase the pH of drilling mud, making it more viscous in nature. Many countries use it to help remove sulfur impurities from low-grade crude oil. It is also used in the paper-making industry in the digestion and bleaching of wood fibers. Sodium hydroxide is used for the decomposition of waste and dead bodies of animals that are killed on roads.

Sodium hydroxide finds applications in various day-to-day applications like the production of soaps and food products like hominy, Chinese noodles, and German pretzels. Its most common and simple application is the production of NaCl or common salt. In homes, it is also used to clean ovens and drain cleaner.

It is used as an industrial cleaning agent, especially in degreasing equipment. It is also used in fuel cell production and many other applications. The growing application of sodium hydroxide will likely boost its demand in the coming years.

Go from Insight to Action with Our Market Research

You've seen the overview. Now, get the detailed data and strategic analysis you need to stay ahead in the market. Explore our related, in-depth reports. Each report includes comprehensive data, forecasts, and competitive analysis to empower your business decisions.Get in Touch

Interested in this topic? Contact our analysts for more details.

Latest Thought Articles

Top OSAT Companies Driving Semiconductor Assembly and Test Services Worldwide

Recently

EV Charging Stations Market Outlook: Smart Charging, Fast Charging, and Regional Expansion

Recently

Future of Corporate Wellness: Global Trends and Regional Outlook

Recently

Regional Breakdown of the Mechanical Keyboard Market: Who Leads and Why?

Recently