The Future of Construction: How Ready-Mix Concrete is Revolutionizing the Industry

The global construction market is expanding and witnessing huge investments complemented by population growth, rapid urbanization, favorable government policies, and more. At the same time, the construction industry is evolving in terms of innovation and efficiency.

Infrastructure development is accelerating across the globe and needs materials that can reduce labor and time while ensuring consistency in quality. Ready-Mix Concrete has changed the way construction companies operate and deliver projects over the last decade.

Ready-Mix Concrete is manufactured in a controlled environment, leading to consistent quality. The main advantage of this is being ready-to-use on arrival at the construction site and in turn, reduced construction time. Thus, making it a more viable and effective alternative to site-mix concrete. Further, in the era of environmental consciousness, Ready-Mix Concrete is witnessing increased adoption as this is a sustainable option with a lesser carbon footprint and wastage.

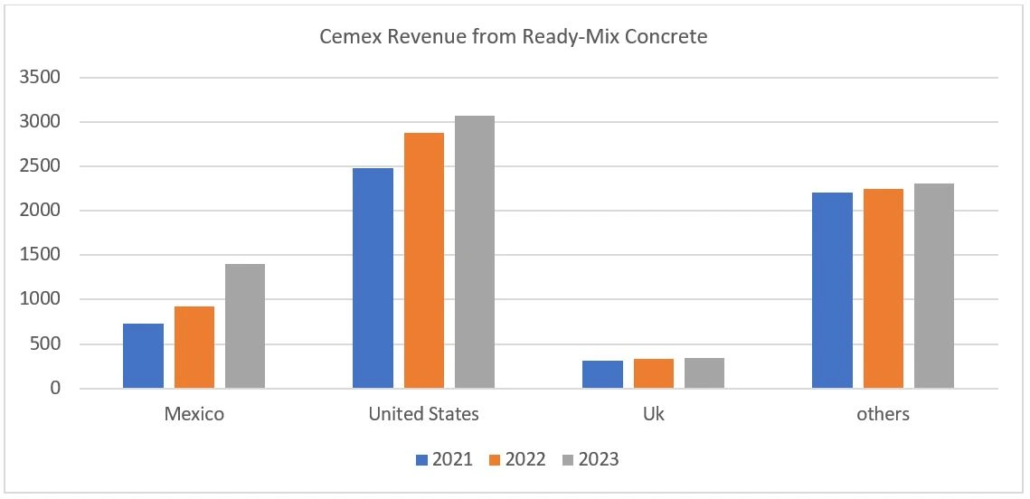

Source: Cemex Annual Report

All these advantages, combined with problems associated with on-site concrete preparation, make Ready-Mix Concrete drive the construction industry. The companies are expanding their footprint to tap into the existing opportunities and harness the huge potential coming along with the growth in the construction sector.

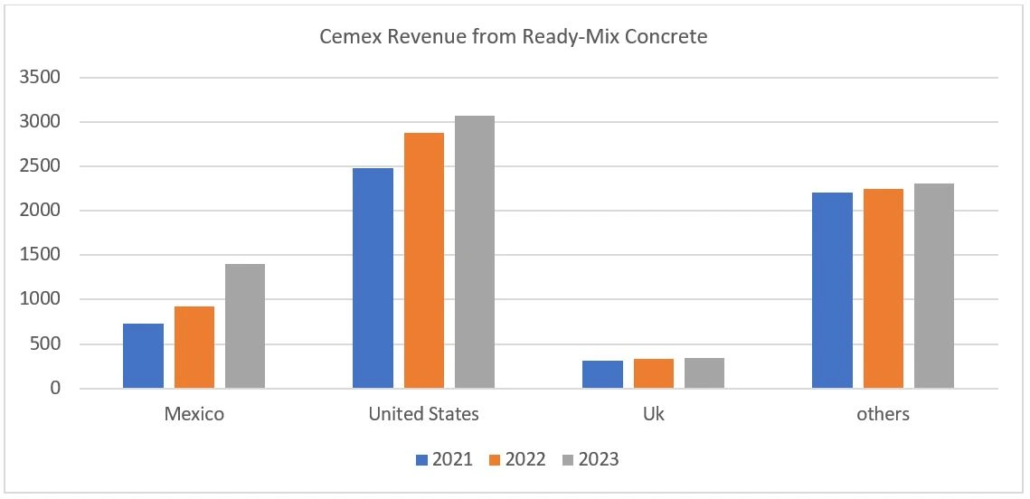

Source: Cemex Annual Report

All these advantages, combined with problems associated with on-site concrete preparation, make Ready-Mix Concrete drive the construction industry. The companies are expanding their footprint to tap into the existing opportunities and harness the huge potential coming along with the growth in the construction sector.

Explore the Ready-Mix Concrete Market

Ready-Mix Concrete is revolutionizing construction. Get our comprehensive report to uncover market size, growth forecasts, and key trends driving this industry.- ? Detailed Market Analysis & Forecasts

- ? Key Player Strategies & Market Share

- ? Regional Growth Opportunities

Advantages Offered by Ready-Mix Concrete

Specialized batching plants manufacture Ready-Mix Concrete, a customized product, to meet the demand of the construction industry as per specifications. They mix it in the right proportion to maintain the highest level of quality. Ready-Mix Concrete offers many benefits that site-mix concrete lacks, thus augmenting its demand within the construction sector. Quality and Consistency: Because specialized batching plants prepare Ready-Mix concrete in a controlled environment where they measure and blend it precisely, the quality and consistency are maintained. Cost-effectiveness: As Ready-Mix concrete is prepared in huge quantities; there are economies of scale at play. This makes the Ready-Mix concrete companies supply their product at a lower cost than the site-mix concrete cost leading to widespread application across the construction sector. Versatility and Durability: Ready-Mix concrete can be tailored to meet the specific demand of any project. This provides the necessary strength, durability, and other benefits. This ensures that it can withstand harsh weather conditions and chemical exposure, thus making it a better option for residential, commercial, and industrial construction projects. Sustainability: Ready-mix concrete production is sustainable. It significantly contributes to the environmental impact of construction projects due to its energy efficiency and reduced carbon emissions. This makes Ready-Mix concrete a perfect product for the construction industry, which has faced continuous criticism from activists who believe that there is a lack of participation from the construction companies due to their lackluster approach toward sustainability. The increased adoption has also led to the Ready-Mix Concrete manufacturers witnessing consistent revenue growth. One such example is Cemex, one of the major ready-mix concrete companies of Mexico, which generated revenues of $7,116 million in the year 2023 from ready-mix concrete, increasing from $5,732 million in the year 2021, an increase of 24.14%. Source: Cemex Annual Report

All these advantages, combined with problems associated with on-site concrete preparation, make Ready-Mix Concrete drive the construction industry. The companies are expanding their footprint to tap into the existing opportunities and harness the huge potential coming along with the growth in the construction sector.

Source: Cemex Annual Report

All these advantages, combined with problems associated with on-site concrete preparation, make Ready-Mix Concrete drive the construction industry. The companies are expanding their footprint to tap into the existing opportunities and harness the huge potential coming along with the growth in the construction sector.

Discover the Concrete Admixtures Market

Enhance your understanding of sustainable construction materials. Our report on the Global Concrete Admixtures Market provides insights into innovations and market trends.The Future is the Era of the Green Economy, i.e., Ready-Mix Concrete over On-Site Concrete

This is the era of environmental consciousness. Industries need to adapt to the changing environment; only then will they be able to survive in the future. A report by Oxford Economics predicts that the construction industry will reach US$13.9 trillion by 2037 from US$9.7 trillion in 2022, driven by the green economy. This necessitates the construction industry to adapt to sustainable construction practices, allowing the participants to harness future opportunities. As per International Finance Corporation, a World Bank group, “Construction value chains account for 40% of energy and industrial-related carbon dioxide emissions globally and this contribution can grow significantly with increasing population, rapid urbanization, and rising income level, necessitating the demand for better housing and commercial buildings”. As a result, the construction industry's meeting the sustainable goals will be pivotal to the climate future of the world. Carbon emissions can be reduced significantly within the construction industry by adopting new technologies, utilizing sustainable raw materials, and implementing appropriate policies. Governments across the world are formulating stringent rules and regulations to curb the carbon emissions from the construction industry to achieve net-zero carbon emissions by 2050. For example, the United States Environmental Protection Agency announced a grant selection for $160 million to support the shift to cleaner construction materials to reduce climate pollution linked to the production of construction materials and products. Governments across the globe are undertaking similar initiatives. This poses a new challenge for the construction industry as it needs to align itself with the new laws and regulations to continue witnessing growth. In the European Union (EU), the construction industry accounts for 35% of the EU’s total waste generation. Material extraction, manufacturing of construction products, and construction and renovation of buildings are estimated to contribute 5-12% of total national greenhouse gas emissions. It is estimated that if greater material efficiency were applied, it could result in saving 80% of those greenhouse gas emissions. Thus, the EU has adopted the Construction Products Regulations to require CE marking for all products that fall under the scope of the regulation. Additionally, India, which has the fastest-growing construction industry, fueled by the Smart City Mission, Bharat Mala project, Sagar Mala project, Pradhan Mantri Awas Yojana, and many more, has seen capital investments grow by 5.2 times (in Rupees) in 2023 compared to 2014. The Indian government has pledged during COP26 to reduce carbon emissions by 1 billion tonnes by 2030, and the construction sector remains the primary focus as it accounts for 17% of the nation’s total greenhouse gas emissions. The construction industry is growing exponentially, but the highest share of growth lies in the green economy. As per the International Finance Corporation, “Global Domestic and Foreign Private Green Debt Finance for construction Decarbonization has increased 20-fold in the last five years from $15-20 billion in 2017 to around $220 billion in 2021”. The construction industry needs to adopt best practices that would help it reduce its carbon emissions. Ready-Mix Concrete is one of the ways to achieve the above goals, it helps in reducing carbon by reducing wastage during production and saving transportation emissions. Furthermore, evolving technologies like artificial intelligence (AI) and IoT would continue assisting the Ready-Mix Concrete players to have precise control over the production of RMC, leading to greater efficiency and consistency. Thus, Ready-Mix concrete with its new advancements is crucial for the construction industry which is facing challenges due to climate change.Understand the Smart Cities Market

India’s construction boom is driven by initiatives like the Smart Cities Mission. Dive into our Smart Cities Market report for insights into urban development trends and opportunities.Innovations in the Ready-Mix Concrete Market

With the advancement in technology like Artificial Intelligence and the Internet of Things (IoT), the Ready-Mix Concrete sector is witnessing innovations. Earlier, concrete batching involved a manual process, but with the advent of automated batching systems, computer-controlled algorithms accurately measure and mix the concrete solutions, making the final product more qualitative and consistent. Digitization and the Internet of Things (IoT) are significantly impacting the Ready-Mix Concrete sector, as sensors and IoT devices monitor and collect data about temperature, slump during mixing, etc., leading to better quality concrete mix. Mobile technology, self-consolidating concrete, and the use of environment-friendly cementitious materials like fly ash, slag, and silica fume help to reduce the carbon footprint. Thus, advancements and innovations in the Ready-Mix Concrete industry provide numerous benefits, leading to increased efficiency, better quality, enhanced sustainability, and the ability to construct better structures.Tapping The Huge Potential of the Existing Ready-Mix Concrete Market

India has the fastest-growing construction industry.Active Voice:

Reports by Invest India predict that the Indian construction industry will reach $1.4 trillion by 2025. This growth in the construction industry is driven by its vast population, high rate of urbanization, and increased government spending. For example, per the annual report of 2023-24 released by the Ministry of Road Transport and Highways, Government of India, there was an approximately 4 times increase in government capital expenditure from USD 8.5 billion in 2013-14 to USD 36.0 billion in 2023-24.

Still, India’s Ready-Mix Concrete Market is in its infancy. Developed countries like the USA, use 80 to 85% of cement consumption in the form of Ready-Mix concrete (Source: National Ready Mixed Concrete Association), but the same for India is only 5%. The country still accounts for 80 to 82% of cement consumption as on-site consumption. Countries like India and similar emerging economies have a huge untapped market for Ready-Mix Concrete. The companies should focus on these markets to maximize their revenues and expand their footprint.Go from Insight to Action with Our Market Research

You've seen the overview. Now, get the detailed data and strategic analysis you need to stay ahead in the construction materials market. Explore our related, in-depth reports. Each report includes comprehensive data, forecasts, and competitive analysis to empower your business decisions.Get in Touch

Interested in this topic? Contact our analysts for more details.

Latest Thought Articles

Top OSAT Companies Driving Semiconductor Assembly and Test Services Worldwide

Recently

EV Charging Stations Market Outlook: Smart Charging, Fast Charging, and Regional Expansion

Recently

Future of Corporate Wellness: Global Trends and Regional Outlook

Recently

Regional Breakdown of the Mechanical Keyboard Market: Who Leads and Why?

Recently