Bio PET Film Market: A New Development in Eco-Friendly Packaging

Polyethylene terephthalate, or bio-PET, is a polyester film that serves as PET's alternative. It can be used in quite a few settings, along with automotive interiors, packaging, wrapping films, and electrical insulation. When compared to traditional PET packaging, bio-PET offers packaging that is both transparent and greater affordable. In addition to imparting excessive tensile power, dimensional stability, aroma barrier, electrical insulation, and environmental safety, it's far less high-priced than petroleum-derived assets. The market for bio-PET film might be driven by the fashion toward bioplastics, governmental regulations, and the growing use of bio-PET film in packaging, cosmetics, prescribed drugs, and different industries. Due to the shift in various quit-use industries closer to environment-pleasant merchandise and packages, the marketplace for Bio-PET film is expected to grow during the forecast period.

Globally, the rising regard for sustainability and ecology by individuals stimulates market expansion. In addition, rising favor for bioplastics as well as government policies that are pro-bioplastic are some of the factors that contribute to the growth of bio-PET film markets including; growing usage in printing, packaging, electrical & electronics, pharmaceuticals and cosmetics industries.

Moreover, public growing concerns about plastic waste are something that is driving the bio-PET film market in the region. In the forecast period, market forecasters predict that bio-PET film demand will be boosted by government campaigns aimed at reducing overall single-use plastics usage in the country. In such government programs like "Clean India Mission", single-use plastic wraps were banned 2022.

Global adoption Trends

Bio-PET films are widely utilized in laminating applications because of their superior optical qualities, which include high transparency and clarity. This is because they are perfect for laminating documents, cards or photos where it is necessary to keep the appearance and visibility of the underlying material unchanged. Other than that bio-PET films have no shrinkage which allows them to withstand heat and moisture without changing their original size. To avoid warping or distortion of laminated items, dimensional stability during the lamination process is essential. These films are also robust and long-lasting, immune to chemicals and temperature changes.

Moreover, the boom in the electrical industry and the increasing call for green insulating materials are associated with the developing use of bio-PET films in electrical insulation. Bio-PET movies are superb at insulating towards electric cutting-edge and have accurate dielectric features. They may be utilized in excessive-voltage applications due to their excessive dielectric energy. These films display a low dissipation element, meaning that when uncovered to alternating electrical contemporary, they lose very little power. These movies are flexible and effortlessly moldable or formed to fulfil the specific requirements of electrical additives. They additionally have low thermal expansion, can resist an extensive range of temperatures, and hold their length and shape over a huge temperature range.

End Use Case

The market in food packaging is being driven by the growing need for packaging, particularly in the food industry. The market for bio-PET is therefore anticipated to grow as a result. Growing environmental concerns and a ban on single-use plastics are causing an upward need for the use of biodegradable plastics in the packaging industry. One such prohibition is the only one made by way of the Indian government in July 2022 on generating, selling, using, importing, storing and distributing single-use plastic substances. The call for environmentally quality and biodegradable alternatives to conventional plastics, like bio-PET, is expected to grow due to those guidelines.

Further, consumer preferences toward eco-friendly products and the increasingly environmentally aware individuals are driving the demand for sustainable electronics. Manufacturers have been incorporating bioplastics in several electric and electronic equipment over worries about growing plastic waste and increasing demand for electronic gadgets.

Market Dynamics and Drivers

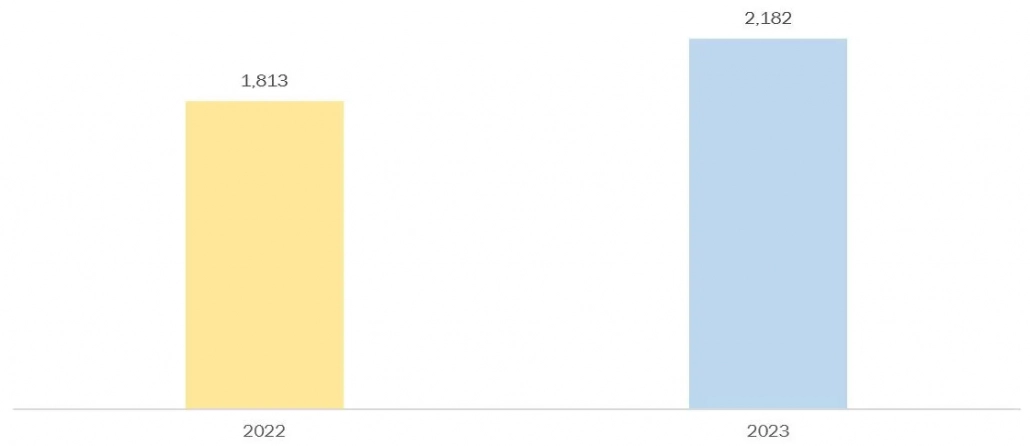

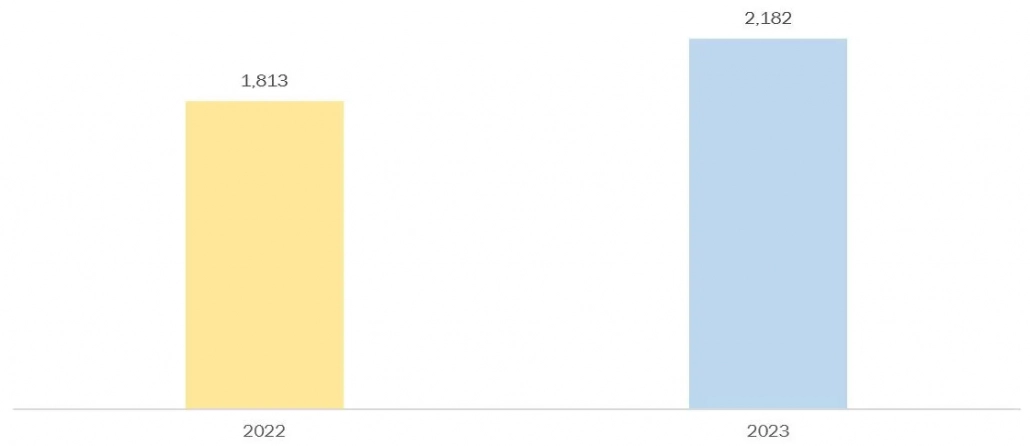

The market for bio-PET film has elevated as a result of developing recognition of the production and alertness of bio-primarily based PET. The European Bioplastics (Association of Bioplastics) expects there will be a massive increase in global bioplastics production capacity from 2.18 million tonnes this year (2023) to about 7.43 million tonnes by 2028.

Figure 1: Global Bioplastics Production, in 1,000 Tonnes, 2022 to 2023

Source: European Bioplastics

Japan’s government is also encouraging the use of bio-degradable plastics derived from plants as a measure to curb ocean pollution by plastics. Policies are developed by using the Japan Clean Ocean Material Alliance, or CLOMA, to promote using recycled or biodegradable plastics. Consequently, there may be a growing marketplace for bio-PET products, that is using up using bio-primarily based PET with the aid of a variety of give-up users and improving the outlook for the bio-PET movie industry.

The use of Bio-PET is common in bottling companies because many organizations are no longer comfortable using products made from non-renewable resources; hence, the increased adoption of Bio-PET packaging. Additionally, there’s an increased interest from buyers regarding biobased goods.

Bio-PET packaging is responsible for the access to clean drinking water by billions of people as well as for the development of the beverage industry. It is possible to recycle it into different kinds of products that are flexible, provisional, secure as well as light. It furthermore exerts good mechanical and barrier properties.

Key Developments

Source: European Bioplastics

Japan’s government is also encouraging the use of bio-degradable plastics derived from plants as a measure to curb ocean pollution by plastics. Policies are developed by using the Japan Clean Ocean Material Alliance, or CLOMA, to promote using recycled or biodegradable plastics. Consequently, there may be a growing marketplace for bio-PET products, that is using up using bio-primarily based PET with the aid of a variety of give-up users and improving the outlook for the bio-PET movie industry.

The use of Bio-PET is common in bottling companies because many organizations are no longer comfortable using products made from non-renewable resources; hence, the increased adoption of Bio-PET packaging. Additionally, there’s an increased interest from buyers regarding biobased goods.

Bio-PET packaging is responsible for the access to clean drinking water by billions of people as well as for the development of the beverage industry. It is possible to recycle it into different kinds of products that are flexible, provisional, secure as well as light. It furthermore exerts good mechanical and barrier properties.

Key Developments

Source: European Bioplastics

Japan’s government is also encouraging the use of bio-degradable plastics derived from plants as a measure to curb ocean pollution by plastics. Policies are developed by using the Japan Clean Ocean Material Alliance, or CLOMA, to promote using recycled or biodegradable plastics. Consequently, there may be a growing marketplace for bio-PET products, that is using up using bio-primarily based PET with the aid of a variety of give-up users and improving the outlook for the bio-PET movie industry.

The use of Bio-PET is common in bottling companies because many organizations are no longer comfortable using products made from non-renewable resources; hence, the increased adoption of Bio-PET packaging. Additionally, there’s an increased interest from buyers regarding biobased goods.

Bio-PET packaging is responsible for the access to clean drinking water by billions of people as well as for the development of the beverage industry. It is possible to recycle it into different kinds of products that are flexible, provisional, secure as well as light. It furthermore exerts good mechanical and barrier properties.

Key Developments

Source: European Bioplastics

Japan’s government is also encouraging the use of bio-degradable plastics derived from plants as a measure to curb ocean pollution by plastics. Policies are developed by using the Japan Clean Ocean Material Alliance, or CLOMA, to promote using recycled or biodegradable plastics. Consequently, there may be a growing marketplace for bio-PET products, that is using up using bio-primarily based PET with the aid of a variety of give-up users and improving the outlook for the bio-PET movie industry.

The use of Bio-PET is common in bottling companies because many organizations are no longer comfortable using products made from non-renewable resources; hence, the increased adoption of Bio-PET packaging. Additionally, there’s an increased interest from buyers regarding biobased goods.

Bio-PET packaging is responsible for the access to clean drinking water by billions of people as well as for the development of the beverage industry. It is possible to recycle it into different kinds of products that are flexible, provisional, secure as well as light. It furthermore exerts good mechanical and barrier properties.

Key Developments

- In September 2023, LOTTE Chemical came up with ‘ECOSEED’ line comprised largely of new environmentally friendly raw materials. ECOSEED contains physically and chemically recycled materials such as post-consumer use recycled materials and bioplastics like Bio-PET. It is expected that through this strategy the company will be able to achieve the 2030 goal of supplying up to one million tons of ‘ECOSEED’ product which is a resource circulation substance.

- In June 2023, A non-binding Memorandum of Understanding (MOU) was signed to establish a joint venture between Carbios, a biotech company focused on developing biological solutions for plastic and textile recycling, and Indorama Ventures Public Company Limited, a leading global producer of sustainable chemicals. The establishment of the first PET recycling facility in the world is the goal of this collaboration in France.

- In May 2023, Indorama Ventures Public Company Limited, a top manufacturer of virgin and recycled PET resins, and Origin Materials, Inc., a company that specializes in carbon-negative materials, joined forces strategically to accelerate the large-scale production of bio-based materials. Films, textiles, automotive parts, packaging, and other industries could all benefit from the use of these materials. The collaboration aims to create co-polyesters, bio-PTA, bio-based chemical furan-dicarboxylic acid and advanced bio-based PET plastics that have advantages over traditional PET plastics.

Get in Touch

Interested in this topic? Contact our analysts for more details.

Latest Thought Articles

Top OSAT Companies Driving Semiconductor Assembly and Test Services Worldwide

Recently

EV Charging Stations Market Outlook: Smart Charging, Fast Charging, and Regional Expansion

Recently

Future of Corporate Wellness: Global Trends and Regional Outlook

Recently

Regional Breakdown of the Mechanical Keyboard Market: Who Leads and Why?

Recently