3D Printing – The New Normal in Global Manufacturing

Traditionally, prototype development and customized manufacturing primarily involved using the conventional manual modeling techniques along with computer-controlled machining in which subtractive manufacturing methodologies were applied. This technique is relatively labor-intensive and resulted in limited time for product designing and innovation. Furthermore, to achieve the goal of time-to-market, the product designing optimization ability was severely reduced as the prototypes were only made ready late in the designing process. This limitation of conventional manufacturing techniques has been addressed by the introduction of 3D printing technology.

3D printing is a process that involves the construction of a product or object from a digital file. The 3D printing technique is considered to be more efficient and effective in comparison to traditional methods through its combination of functionality, ease of use, high design speed, and relatively lower cost. The ability of 3D printers to eliminate the need for complex manufacturing set-ups tends to drive down the operation cost significantly while simultaneously improving the development cycle of the product. Furthermore, its applications in concept modeling, design review and validation, pattern making, and direct manufacturing among others is further leading to its growing demand with the 3D printing market size estimated to grow from US$9.190 billion in 2018 to US$39.640 billion in 2024 at a CAGR of 27.59%.

Enterprises Using 3d Printing, % of Enterprise, 2018

Source: Eurostat

The proliferation of 3D printing technology is still a small, but growing market segment. According to Eurostat, only 4% of the enterprises in the European Union-28 are utilizing 3D printing technology, with the highest proportion being observed in Finland. Only 5% of the enterprise in Germany, which is considered an engine of Europe, is making use of 3D printing techniques while 6% of the enterprises in the United Kingdom have adopted the advanced manufacturing and designing solution.

Moreover, even though, China contributes the largest proportion of the global value-added in the manufacturing industry, the adoption of 3D printing technology is still relatively low in comparison to the United States and the European Union. This indicates that the market potential is extremely high, with a large existing manufacturing base, the 3D printing industry is projected to surge rapidly in China in the next five years.

Proportion of Manufacturing Value Added by Country in 2019

Source: World Bank

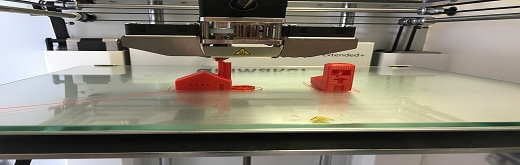

3D printers are essentially the hardware of the 3D printing ecosystem that builds parts on the basic principle: a digital CAD model is turned into a physical three-dimensional object by joining material layer by layer. Earlier, the sales of 3D printers were primarily driven by the prototyping application used in limited industries due to their high cost. However, today, the scenario has changed, and manufacturers have come up with several advanced technologies that have significantly reduced the prices of 3D printers and have extended its applicability to creating complex components parts and others. Its growing utility in the manufacturing and commercial sectors has significantly resulted in significant growth of the 3D printing market.

Services are an integral part of the 3D printing market since it ensures that end-user industries can make use of 3D printing technology without much investment in buying the machines. The businesses across industries make use of professional 3D printing services to get access to other additive manufacturing technologies than the ones they own in-house. The high cost of some technologies like material jetting significantly leads to higher adoption of these services, thus driving the 3D printing services market growth. As a result, manufacturers like Stratasys, HP, 3D Hubs, Shapeways, Inc., Soch3D, and others are increasingly providing 3D printing services for various end-user industries. For instance, 3D Hubs provide online 3D printing services and other technology-based services like MJF 3D printing service for prototyping and small-batch production.

Recent Market Developments

- In July 2020, 9T labs entered into a collaboration with Setforge to bring additive manufacturing CRFP to large scale production.

- In June 2020, Zortrax announced the launch of an upgraded version of its M200 Plus and M300 Plus 3D printers.

- Redefine Meat is currently utilizing 3D printing technology to manufacture plant-based meat.

- Materialise, in May 2020, launched Mindware – an advisory service that offers technology insights on the use of 3D printing technology.

- FabRx Ltd announced in April 2020 the availability of its first pharmaceutical 3D printer “M3DIMAKER™” for the manufacture of personalized medicine.

- Modix – an Israel based large scale 3D printer developer, launched a 3D printer – Big120Z.

- Essentium Inc entered into a partnership with LEHVOSS Group in March 2020 to develop high-performance materials for industrial-scale additive manufacturing.

- Similarly, Oceanz 3D Printing has recently announced its partnership with AM-Flow to develop completely automated additive manufacturing lines.

- In February 2020, Intech Additive Solutions – a Bangalore based company, specializing in direct metal laser sintering has launched its new varieties of 3D printers.

- Wipro3D in collaboration with Indian Institution of Science developed India’s first industry-grade metal 3D printing machine.

Plastic Is the Dominant 3d Printing Material

The market for 3D printing materials is expanding at an unprecedented scale owing to the increasing adoption of 3D printing solutions for industrial and residential purposes. Furthermore, the rapid advancements in the industry and innovations allowing for newer materials in the market are estimated to further expand this growth in the coming years. Plastics are the most commonly available 3D printing material. They are used extensively in desktop and residential 3D printers due to their lower cost and easy workability. Plastics are used in multiple 3D printing technologies ranging from vat photopolymerization to FDM to powder bed fusion. As plastics are easier to work with and possess multiple distinctive properties, they are highly sought after for residential and commercial 3D printed solutions. In addition to this, the availability of biodegradable plastics has also instigated the use of these materials in other industries such as healthcare for the manufacturing of medical implants, thus further expanding the market potential for plastics. Furthermore, increasing market innovations and a mixture of plastic resins with other materials such as wood are also estimated to increase the scope for the segment to grow further. Moreover, PLA is also estimated to hold a noteworthy share in the market owing to its extensive use in residential 3D printing and is projected to witness good growth on account of increasing focus towards biodegradable plastic sources. PET is estimated to hold a decent market share in the 3D printing materials market due to its limited usability in 3D printing.

High Potential in the Semiconductor Industry

The growing trend of miniaturization is putting pressure on the firms in the semiconductor industry to break the physical limit in the device. The conventional manufacturing process bound the designers with structural and planarity issues. Since 3D printing technology does not follow the subtractive methodology, its utility in the semiconductor is high, allowing the manufacturers to 3D print the semiconductor components efficiently and effectively. Moreover, it also eliminates the need for assembly and soldering, allowing semiconductor devices to be directly fabricated on 3D printed PCB’s.